Executive Summary

The convergence of geopolitical tensions, climate volatility, and technological disruption has elevated supply chain resilience from operational consideration to strategic imperative. This comprehensive guide examines proven frameworks, emerging technologies, and practical strategies for building adaptive, robust supply chain capabilities that deliver competitive advantage during periods of uncertainty.

Building Supply Chain Resilience: A Strategic Framework for Uncertain Times

(构建2025年韧性供应链的战略与战术指南)

1 · The Strategic Evolution of Supply Chain Resilience

Supply chain resilience has transformed from a defensive risk management function to a proactive source of competitive advantage. Organizations that view resilience as merely cost protection miss its potential as a growth enabler and market differentiation tool.

Understanding Modern Supply Chain Volatility

The New Risk Landscape: Contemporary supply chains face unprecedented complexity and interconnected risks that traditional risk management approaches cannot adequately address:

Geopolitical Disruptions:

- Trade Policy Volatility: Rapid changes in tariff structures and trade agreements

- Economic Sanctions: Targeted restrictions affecting specific suppliers and regions

- Border Security Measures: Enhanced screening procedures creating delays and uncertainties

- Currency Fluctuations: Exchange rate volatility affecting cost structures and competitiveness

Environmental and Climate Risks:

- Extreme Weather Events: Hurricanes, floods, and droughts disrupting transportation networks

- Seasonal Pattern Changes: Shifting climate patterns affecting agricultural and manufacturing cycles

- Resource Scarcity: Water, energy, and raw material availability constraints

- Regulatory Response: Environmental compliance requirements affecting operations and costs

Technological Disruptions:

- Cybersecurity Threats: Ransomware and cyber attacks targeting supply chain infrastructure

- Digital Transformation Gaps: Technology adoption disparities creating operational vulnerabilities

- Automation Displacement: Workforce and skill transitions affecting operational capabilities

- Infrastructure Dependencies: Reliance on digital systems creating single points of failure

The Business Case for Resilience Investment

Financial Performance Impact: Research consistently demonstrates that resilient supply chains deliver superior financial performance across multiple metrics:

Revenue Protection and Growth:

- Market Share Preservation: Ability to maintain customer service during disruptions

- Premium Pricing Opportunities: Reliability premium for consistent supply performance

- Market Expansion: Confidence to enter new markets with robust supply capabilities

- Customer Relationship Strengthening: Enhanced loyalty through consistent performance

Cost Optimization Through Resilience:

- Reduced Emergency Costs: Lower expenses for expedited shipping and emergency sourcing

- Improved Working Capital: Optimized inventory levels through better demand prediction

- Insurance Cost Reduction: Lower premiums through demonstrated risk management capabilities

- Operational Efficiency: Streamlined processes reducing waste and inefficiency

Strategic Competitive Advantages:

- First-Mover Benefits: Ability to capture market opportunities during competitor disruptions

- Supplier Relationship Leverage: Preferred customer status with key suppliers

- Technology Leadership: Advanced capabilities attracting top talent and partners

- Brand Value Enhancement: Reputation for reliability and sustainability

2 · Comprehensive Framework: The Five Pillars of Supply Chain Resilience

Effective supply chain resilience requires integration across five core capability areas. Each pillar reinforces the others, creating a comprehensive system that can adapt to diverse disruption scenarios.

Pillar 1: Predictive Intelligence and Real-Time Visibility

Advanced Analytics Integration: Modern supply chain resilience depends on sophisticated data analytics capabilities that can identify potential disruptions before they impact operations:

Machine Learning Applications:

- Demand Forecasting: Advanced algorithms incorporating multiple data sources for improved accuracy

- Disruption Prediction: Pattern recognition systems identifying potential supply chain interruptions

- Route Optimization: Dynamic routing algorithms adapting to real-time conditions

- Inventory Optimization: AI-driven inventory positioning based on risk and demand patterns

Data Integration Architecture:

- Multi-Source Data Fusion: Integration of internal systems with external data sources

- Real-Time Processing: Stream processing capabilities for immediate response to changing conditions

- Predictive Modeling: Statistical models forecasting potential disruption scenarios

- Automated Decision Support: System recommendations for operational adjustments

Control Tower Implementation:

- Centralized Visibility: Single-pane-of-glass view of global supply chain operations

- Exception Management: Automated identification and escalation of operational issues

- Collaborative Platforms: Shared visibility across internal teams and external partners

- Performance Monitoring: Real-time tracking of key performance indicators and trends

Pillar 2: Network Agility and Geographic Diversification

Strategic Network Design: Building resilient supply chains requires thoughtful geographic distribution that balances efficiency with risk mitigation:

Diversification Strategies:

- Multi-Region Sourcing: Supplier relationships across multiple geographic regions

- Nearshoring Initiatives: Bringing production closer to major markets for reduced risk

- Hub-and-Spoke Models: Regional distribution centers providing flexibility and responsiveness

- Backup Capacity Arrangements: Contingency agreements with alternative suppliers and service providers

Flexibility Mechanisms:

- Scalable Operations: Ability to rapidly increase or decrease production volumes

- Modal Flexibility: Multiple transportation options for different scenarios

- Inventory Positioning: Strategic stock placement for rapid response to disruptions

- Supplier Qualification: Pre-qualified alternative suppliers ready for activation

Cost-Service Optimization:

- Total Cost Modeling: Comprehensive analysis including risk costs and service levels

- Service Level Agreements: Clear performance standards with flexibility provisions

- Dynamic Routing: Real-time adjustment of transportation routes based on conditions

- Capacity Management: Optimal utilization of resources across multiple facilities

Pillar 3: Supplier Relationship Management and Ecosystem Resilience

Strategic Supplier Development: Resilient supply chains require strong, collaborative relationships with suppliers who share resilience commitments:

Supplier Assessment and Development:

- Risk Assessment Frameworks: Comprehensive evaluation of supplier resilience capabilities

- Performance Monitoring: Ongoing tracking of supplier financial health and operational performance

- Capability Development: Investment in supplier capabilities and process improvements

- Innovation Collaboration: Joint development of new products and process improvements

Diversification and Backup Planning:

- Multi-Sourcing Strategies: Multiple suppliers for critical components and services

- Supplier Qualification Programs: Systematic evaluation and onboarding of new suppliers

- Contingency Agreements: Pre-negotiated arrangements with backup suppliers

- Risk Sharing Mechanisms: Contractual arrangements for shared risk management

Ecosystem Visibility and Collaboration:

- Tier 2+ Visibility: Understanding of deeper supplier relationships and dependencies

- Information Sharing: Real-time communication of demand, capacity, and risk information

- Joint Planning: Collaborative forecasting and capacity planning processes

- Shared Technology Platforms: Integrated systems enabling seamless collaboration

Pillar 4: Technology Integration and Digital Transformation

Digital Twin Technology: Digital representations of physical supply chain assets enable sophisticated scenario modeling and optimization:

Digital Twin Applications:

- Network Modeling: Virtual representation of entire supply chain network

- Scenario Simulation: Testing the impact of various disruption scenarios

- Optimization Algorithms: Continuous improvement of network configuration and operations

- Predictive Maintenance: Anticipating equipment needs and preventing failures

Advanced Technology Integration:

- Internet of Things (IoT): Sensor networks providing real-time asset and shipment monitoring

- Blockchain Technology: Secure, transparent tracking of products and transactions

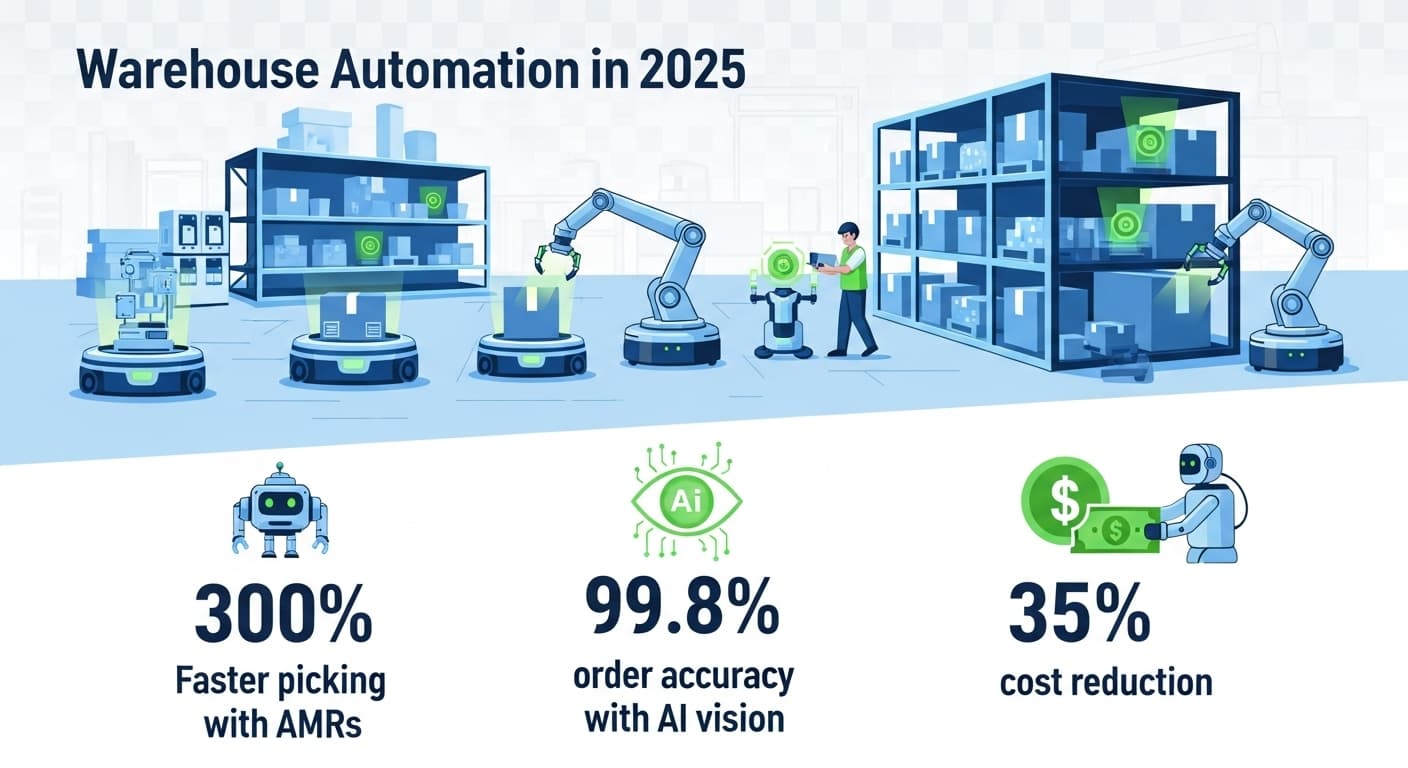

- Robotic Process Automation: Automated handling of routine tasks and processes

- Artificial Intelligence: Machine learning algorithms optimizing decisions across operations

Data and Analytics Infrastructure:

- Cloud Computing: Scalable, flexible computing resources for advanced analytics

- Edge Computing: Local processing capabilities for real-time decision-making

- Data Governance: Standards and processes ensuring data quality and security

- Cybersecurity: Comprehensive protection of digital assets and information

Pillar 5: Sustainability and Compliance Integration

ESG Integration in Supply Chain Design: Environmental, social, and governance considerations are increasingly central to supply chain resilience:

Environmental Sustainability:

- Carbon Footprint Management: Comprehensive measurement and reduction of greenhouse gas emissions

- Circular Economy Principles: Design for reusability, recyclability, and waste reduction

- Resource Efficiency: Optimization of water, energy, and material usage

- Environmental Risk Assessment: Evaluation of climate-related risks to operations

Social Responsibility:

- Labor Standards: Ensuring fair labor practices throughout the supply chain

- Community Impact: Positive contributions to local communities where operations are located

- Diversity and Inclusion: Promoting diverse supplier relationships and inclusive practices

- Human Rights: Protection of human rights throughout global operations

Governance and Compliance:

- Regulatory Compliance: Adherence to all applicable laws and regulations

- Ethical Business Practices: Transparent, honest dealings with all stakeholders

- Risk Management: Systematic identification and mitigation of operational risks

- Continuous Improvement: Ongoing enhancement of ESG performance and reporting

3 · Supply Chain Resilience Maturity Assessment

Understanding organizational maturity in supply chain resilience enables targeted improvement efforts and realistic goal setting for capability development.

Maturity Level Framework

Level 0: Reactive Response

Characteristics:

- Manual Processes: Heavy reliance on spreadsheets and email communication

- Limited Visibility: Poor understanding of supply chain performance and risks

- Crisis Management: Firefighting approach to disruption response

- Siloed Operations: Disconnected functional areas with limited coordination

Technology Environment:

- Basic ERP systems with limited integration

- Manual data collection and reporting processes

- Limited supplier communication tools

- Reactive customer service approaches

Performance Indicators:

- High emergency procurement costs

- Frequent stock-outs and service failures

- Long response times to disruptions

- Customer complaints about service reliability

Level 1: Basic Awareness

Characteristics:

- Static Risk Registers: Basic documentation of known risks

- Limited Tracking: Basic shipment and inventory visibility

- Reactive Planning: Response to disruptions after they occur

- Functional Integration: Some coordination between departments

Technology Environment:

- Transportation Management Systems (TMS) implementation

- Basic visibility platforms for shipment tracking

- Supplier portals for basic communication

- Standard reporting and dashboard tools

Performance Indicators:

- Improved visibility into immediate operations

- Reduced emergency costs through better planning

- Enhanced customer communication capabilities

- Basic supplier performance monitoring

Level 2: Adaptive Capabilities

Characteristics:

- Scenario Planning: Modeling of potential disruption scenarios

- Alternative Routing: Pre-planned backup transportation and sourcing options

- Control Tower Operations: Centralized monitoring and coordination

- Predictive Analytics: Early warning systems for potential disruptions

Technology Environment:

- Advanced planning systems with optimization capabilities

- Control tower platforms with real-time monitoring

- Machine learning algorithms for demand forecasting

- Integration platforms connecting multiple systems

Performance Indicators:

- Faster response times to disruptions

- Improved forecast accuracy and inventory optimization

- Enhanced supplier collaboration and performance

- Reduced overall supply chain costs

Level 3: Proactive Resilience (Antifragile)

Characteristics:

- Predictive Disruption Management: Adjustment of operations before disruptions occur

- Continuous Optimization: Ongoing improvement of network performance

- Ecosystem Orchestration: Leadership role in supply chain ecosystem resilience

- Value Creation: Generating competitive advantage through resilience capabilities

Technology Environment:

- Digital twin technology for comprehensive network modeling

- AI-driven prescriptive analytics for optimization

- Blockchain-enabled transparency and collaboration

- Advanced cybersecurity and risk management systems

Performance Indicators:

- Competitive advantage through superior reliability

- Revenue growth through enhanced customer service

- Market leadership in sustainability and innovation

- Premium pricing for reliable performance

Industry Benchmarking and Best Practices

Cross-Industry Resilience Comparison: Different industries face unique resilience challenges and have developed specialized approaches:

Technology and Electronics:

- Challenges: Rapid product lifecycles, complex global supply networks, geopolitical risks

- Best Practices: Dual-sourcing strategies, advanced demand sensing, supplier financial monitoring

- Key Metrics: Time-to-recovery, forecast accuracy, supplier diversification index

Automotive Manufacturing:

- Challenges: Just-in-time manufacturing, complex supplier tiers, quality requirements

- Best Practices: Supplier development programs, risk assessment frameworks, collaborative planning

- Key Metrics: Production continuity, supplier performance, quality incident rates

Consumer Goods and Retail:

- Challenges: Seasonal demand patterns, fast fashion cycles, sustainability requirements

- Best Practices: Demand sensing technology, flexible manufacturing, ethical sourcing programs

- Key Metrics: Service level achievement, inventory turnover, sustainability compliance

Pharmaceutical and Healthcare:

- Challenges: Regulatory compliance, product safety, critical supply continuity

- Best Practices: Redundant supply sources, regulatory compliance monitoring, temperature-controlled logistics

- Key Metrics: Regulatory compliance rates, product quality indicators, supply continuity

4 · Technology Integration and Digital Transformation Strategies

The successful implementation of supply chain resilience requires sophisticated technology integration that connects systems, processes, and stakeholders across the entire ecosystem.

Advanced Analytics and Artificial Intelligence

Predictive Analytics Applications: Modern supply chains leverage multiple forms of predictive analytics to anticipate and prevent disruptions:

Demand Forecasting Enhancement:

- Multi-Variable Models: Integration of economic indicators, weather data, social media sentiment, and traditional sales data

- Machine Learning Algorithms: Continuous learning systems that improve accuracy over time

- Real-Time Adjustments: Dynamic forecasting that adapts to changing market conditions

- Collaborative Forecasting: Shared forecasting processes with suppliers and customers

Risk Prediction Systems:

- Supplier Risk Monitoring: Financial health tracking, performance trending, and geopolitical risk assessment

- Transportation Risk Assessment: Weather monitoring, port congestion analysis, and route risk evaluation

- Market Risk Analysis: Economic indicator tracking, competitive intelligence, and regulatory change monitoring

- Integrated Risk Modeling: Comprehensive risk models considering multiple interdependent factors

Optimization Algorithms:

- Network Optimization: Continuous adjustment of supply chain network configuration

- Inventory Optimization: Dynamic inventory positioning based on demand patterns and risk assessment

- Route Optimization: Real-time routing decisions considering cost, time, and risk factors

- Capacity Optimization: Optimal allocation of resources across multiple facilities and suppliers

Digital Twin Technology Implementation

Comprehensive Network Modeling: Digital twin technology enables sophisticated modeling and simulation of entire supply chain networks:

Physical Asset Representation:

- Facility Modeling: Detailed representation of manufacturing facilities, warehouses, and distribution centers

- Transportation Networks: Modeling of transportation routes, modes, and capacity constraints

- Equipment Simulation: Virtual representation of manufacturing equipment and material handling systems

- Inventory Modeling: Dynamic representation of inventory levels, locations, and movement patterns

Process Simulation Capabilities:

- End-to-End Process Modeling: Complete representation of supply chain processes from supplier to customer

- Scenario Testing: Simulation of various disruption scenarios and response strategies

- Performance Optimization: Continuous testing of process improvements and configuration changes

- Capacity Planning: Modeling of capacity requirements under different demand scenarios

Real-Time Integration:

- Live Data Feeds: Integration with operational systems for real-time model updates

- IoT Sensor Integration: Direct connection to physical sensors and monitoring devices

- Event-Driven Updates: Automatic model adjustments based on real-world events and changes

- Predictive Modeling: Forward-looking simulations based on current conditions and trends

Connectivity and Collaboration Platforms

Ecosystem Integration: Resilient supply chains require seamless connectivity across all stakeholders and systems:

Multi-Party Collaboration:

- Supplier Integration: Direct connectivity with supplier systems for real-time information sharing

- Customer Connectivity: Integration with customer demand systems and forecasting processes

- Logistics Provider Integration: Seamless connectivity with transportation and logistics service providers

- Regulatory Compliance: Automated compliance reporting and documentation systems

Information Sharing Standards:

- Data Standardization: Common data formats and protocols for seamless information exchange

- API Integration: Application programming interfaces enabling system-to-system communication

- Blockchain Implementation: Secure, transparent tracking of transactions and product provenance

- Cloud-Based Platforms: Scalable, accessible platforms for multi-party collaboration

5 · Case Studies in Resilience Implementation

Understanding real-world implementations provides practical insights into successful resilience strategies and common implementation challenges.

Case Study 1: Global Electronics Manufacturer Transformation

Company Profile: Large multinational electronics manufacturer with complex global supply chain spanning 15 countries and 200+ suppliers

Challenge Context: The company faced multiple simultaneous challenges including trade war tariffs, COVID-19 disruptions, semiconductor shortages, and increasing customer demands for sustainability transparency.

Resilience Strategy Implementation:

Phase 1: Foundation Building (Months 1-6)

- Data Infrastructure: Implementation of integrated data platform connecting ERP, supplier systems, and external data sources

- Visibility Enhancement: Deployment of control tower technology providing real-time visibility into global operations

- Risk Assessment: Comprehensive mapping of supplier risks including financial health, geographic concentration, and single-source dependencies

- Team Development: Creation of dedicated supply chain resilience team with cross-functional representation

Phase 2: Capability Development (Months 7-18)

- Predictive Analytics: Implementation of machine learning models for demand forecasting and disruption prediction

- Supplier Diversification: Qualification and onboarding of alternative suppliers for critical components

- Digital Twin Deployment: Creation of digital representation of key manufacturing and distribution processes

- Automation Integration: Deployment of robotic process automation for routine supply chain tasks

Phase 3: Optimization and Expansion (Months 19-36)

- Advanced Optimization: Implementation of AI-driven optimization algorithms for network configuration

- Ecosystem Integration: Extension of platforms to include tier-2 and tier-3 suppliers

- Sustainability Integration: Comprehensive ESG monitoring and reporting across supply chain

- Continuous Improvement: Establishment of ongoing optimization and improvement processes

Results and Impact:

- Disruption Response Time: Reduced from 5 days to 8 hours for critical disruptions

- Forecast Accuracy: Improved from 65% to 89% at 4-week horizon

- Supply Continuity: Zero production shutdowns due to supply disruptions over 18-month period

- Cost Performance: 12% reduction in total supply chain costs despite resilience investments

- Customer Satisfaction: 15% improvement in on-time delivery performance

- Risk Mitigation: 90% reduction in single-source supplier dependencies

Key Success Factors:

- Executive Commitment: Strong leadership support and investment in transformation

- Cross-Functional Integration: Breaking down silos between functions and departments

- Technology Investment: Significant investment in advanced technology platforms and capabilities

- Supplier Collaboration: Deep engagement with suppliers in resilience initiatives

- Continuous Learning: Ongoing adaptation and improvement based on experience and changing conditions

Case Study 2: Regional Food Distribution Network Resilience

Company Profile: Regional food distributor serving 500+ retail locations across southeastern United States

Challenge Context: Increasing frequency of severe weather events, food safety requirements, and customer demands for local sourcing created complex operational challenges.

Resilience Approach:

Network Redesign Strategy:

- Hub-and-Spoke Evolution: Transition from centralized distribution to regional hub model

- Local Sourcing Programs: Development of local supplier networks for fresh products

- Backup Facility Planning: Establishment of contingency agreements with third-party logistics providers

- Transportation Flexibility: Multi-modal transportation capabilities including refrigerated trucking and rail

Technology Implementation:

- Cold Chain Monitoring: IoT sensors throughout transportation and storage network

- Weather Integration: Predictive weather modeling integrated with operational planning

- Inventory Optimization: AI-driven inventory positioning based on demand patterns and weather forecasts

- Supplier Communication: Real-time communication platforms with local suppliers

Results:

- Weather Disruption Impact: 75% reduction in weather-related service disruptions

- Food Safety Performance: Zero food safety incidents over 24-month implementation period

- Local Sourcing Growth: 40% increase in locally-sourced products

- Customer Service: 20% improvement in product availability during disruptions

- Financial Performance: 8% improvement in gross margins through optimized sourcing and reduced waste

Case Study 3: Automotive Tier-1 Supplier Resilience Program

Company Profile: Major automotive tier-1 supplier providing electronic systems to global automotive manufacturers

Challenge Context: Just-in-time manufacturing requirements, complex regulatory environment, and increasing cybersecurity threats required comprehensive resilience strategy.

Comprehensive Resilience Framework:

Supplier Risk Management:

- Financial Monitoring: Real-time monitoring of supplier financial health and performance

- Diversification Strategy: Development of dual-source strategies for all critical components

- Supplier Development: Investment in supplier capability development and risk mitigation

- Contingency Planning: Pre-negotiated agreements with backup suppliers and emergency response procedures

Cybersecurity Integration:

- Network Security: Comprehensive cybersecurity framework protecting operational technology systems

- Supplier Cybersecurity: Requirements and monitoring for supplier cybersecurity practices

- Incident Response: Rapid response procedures for cybersecurity incidents

- Business Continuity: Backup systems and procedures for continued operations during cyber incidents

Quality and Compliance:

- Regulatory Monitoring: Automated tracking of changing automotive regulations

- Quality Systems: Advanced quality monitoring and control systems

- Traceability: Complete traceability of components and materials throughout supply chain

- Audit and Compliance: Regular auditing and compliance verification procedures

Performance Outcomes:

- Production Continuity: 99.8% production uptime over 18-month period

- Quality Performance: 25% reduction in quality incidents and recalls

- Cybersecurity Resilience: Zero successful cyberattacks affecting production

- Regulatory Compliance: 100% compliance with changing automotive regulations

- Customer Relations: Preferred supplier status with major automotive OEMs

6 · Risk Management and Mitigation Strategies

Effective supply chain resilience requires comprehensive risk management that addresses both known and unknown risks while maintaining operational efficiency and competitive performance.

Comprehensive Risk Assessment Framework

Multi-Dimensional Risk Analysis: Modern supply chain risk management requires analysis across multiple dimensions and time horizons:

Risk Categories:

- Operational Risks: Equipment failures, quality issues, capacity constraints, and process disruptions

- Supplier Risks: Financial instability, performance issues, cybersecurity vulnerabilities, and relationship challenges

- Transportation Risks: Weather disruptions, infrastructure failures, capacity constraints, and regulatory changes

- Market Risks: Demand volatility, competitive pressures, economic fluctuations, and customer changes

- Regulatory Risks: Compliance requirements, trade policy changes, environmental regulations, and safety standards

- Geopolitical Risks: Trade wars, sanctions, political instability, and international relations

Risk Assessment Methodologies:

- Quantitative Analysis: Statistical modeling of historical data to predict future risk probabilities

- Qualitative Assessment: Expert judgment and scenario analysis for emerging or unprecedented risks

- Integrated Risk Modeling: Comprehensive models considering interdependencies between different risk factors

- Dynamic Risk Monitoring: Real-time assessment and adjustment of risk levels based on changing conditions

Mitigation Strategy Development

Proactive Risk Mitigation:

- Diversification Strategies: Geographic, supplier, and modal diversification to reduce concentration risks

- Redundancy Planning: Backup systems, suppliers, and processes to ensure continuity

- Flexibility Mechanisms: Adaptable processes and resources that can adjust to changing conditions

- Early Warning Systems: Monitoring and alert systems for emerging risks and disruptions

Reactive Response Capabilities:

- Incident Response Procedures: Clear procedures for responding to various types of disruptions

- Emergency Resources: Pre-positioned resources and capabilities for rapid response

- Communication Protocols: Effective communication systems for coordinating response efforts

- Recovery Planning: Systematic approaches for returning to normal operations after disruptions

Business Continuity and Crisis Management

Business Continuity Planning:

- Critical Function Identification: Clear understanding of essential business functions and dependencies

- Alternative Operating Procedures: Backup processes and procedures for continuing operations during disruptions

- Resource Requirements: Identification and securing of resources needed for business continuity

- Testing and Validation: Regular testing of business continuity plans and procedures

Crisis Management Framework:

- Leadership Structure: Clear leadership and decision-making authority during crisis situations

- Communication Plans: Internal and external communication strategies for crisis situations

- Stakeholder Management: Coordination with suppliers, customers, and other stakeholders during crises

- Recovery Strategies: Systematic approaches for returning to normal operations and capturing lessons learned

7 · Performance Measurement and Continuous Improvement

Effective supply chain resilience requires comprehensive performance measurement that tracks both resilience capabilities and business outcomes while driving continuous improvement.

Key Performance Indicators for Resilience

Resilience-Specific Metrics:

- Time to Recovery: Speed of returning to normal operations after disruptions

- Disruption Frequency: Number and severity of supply chain disruptions over time

- Supplier Diversification Index: Measurement of supplier concentration and diversification

- Network Flexibility: Ability to adjust operations in response to changing conditions

- Predictive Accuracy: Accuracy of forecasting and early warning systems

- Response Effectiveness: Success rate of disruption response initiatives

Business Performance Integration:

- Service Level Achievement: Customer service performance during normal and disrupted operations

- Cost Performance: Total cost of ownership including resilience investments and disruption costs

- Revenue Protection: Revenue maintained during disruptions compared to potential losses

- Market Share Performance: Competitive position maintenance during industry disruptions

- Customer Satisfaction: Customer perception of reliability and service quality

- Financial Returns: Return on investment for resilience initiatives and capabilities

Continuous Improvement Framework

Learning Organization Principles:

- Knowledge Capture: Systematic documentation of lessons learned from disruptions and responses

- Best Practice Sharing: Internal and external sharing of successful resilience strategies

- Innovation Culture: Encouragement of innovation and experimentation in resilience approaches

- Capability Development: Ongoing development of organizational resilience capabilities

Systematic Improvement Process:

- Performance Analysis: Regular analysis of resilience performance and business outcomes

- Gap Identification: Systematic identification of performance gaps and improvement opportunities

- Initiative Prioritization: Strategic prioritization of improvement initiatives based on impact and feasibility

- Implementation Tracking: Monitoring and management of improvement initiative implementation

- Results Validation: Verification of improvement results and sustainable performance enhancement

8 · Strategic Planning and Implementation Framework

Successfully building supply chain resilience requires strategic planning that aligns resilience investments with business objectives while managing implementation complexity and organizational change.

Strategic Planning Considerations

Business Strategy Alignment:

- Competitive Positioning: Understanding how resilience capabilities support competitive advantage

- Customer Value Proposition: Integration of resilience capabilities with customer value delivery

- Market Opportunity Assessment: Evaluation of market opportunities created by superior resilience

- Investment Prioritization: Strategic allocation of resources across resilience initiatives

Organizational Readiness Assessment:

- Capability Gap Analysis: Understanding current capabilities compared to desired resilience state

- Technology Infrastructure: Assessment of technology requirements and current infrastructure

- Skill and Talent Requirements: Identification of skill gaps and talent development needs

- Change Management Readiness: Organizational capacity for managing complex transformation initiatives

Implementation Strategy Development:

- Phased Implementation: Logical sequencing of resilience initiatives to maximize value and minimize risk

- Quick Win Identification: Early victories that build momentum and demonstrate value

- Risk Management: Identification and mitigation of implementation risks and challenges

- Success Metrics: Clear definition of success criteria and measurement approaches

Change Management and Organizational Development

Cultural Transformation:

- Resilience Mindset: Developing organizational culture that values resilience and continuous improvement

- Risk Awareness: Building organizational awareness of supply chain risks and interdependencies

- Collaboration Enhancement: Strengthening internal and external collaboration capabilities

- Innovation Encouragement: Creating environment that supports innovation and experimentation

Capability Development:

- Training and Development: Comprehensive programs for building resilience-related skills

- Knowledge Management: Systems for capturing, sharing, and applying resilience knowledge

- Leadership Development: Building leadership capabilities for managing complex, uncertain environments

- Team Formation: Creating cross-functional teams with clear resilience responsibilities

Technology Implementation Strategy

Technology Architecture Planning:

- Integration Requirements: Understanding system integration needs and dependencies

- Scalability Considerations: Designing technology architecture for future growth and expansion

- Security Requirements: Comprehensive cybersecurity considerations for resilience technology

- Data Governance: Standards and processes for managing resilience-related data

Implementation Approach:

- Pilot Program Strategy: Limited-scope implementations to test and refine approaches

- Vendor Management: Selection and management of technology vendors and implementation partners

- User Adoption: Strategies for ensuring successful technology adoption across the organization

- Performance Monitoring: Systems for tracking technology performance and business value

9 · Future Trends and Emerging Considerations

Understanding emerging trends and future considerations enables organizations to develop resilience strategies that remain effective as supply chain complexity and volatility continue to evolve.

Technology Evolution and Impact

Artificial Intelligence Advancement:

- Autonomous Decision Making: AI systems capable of making complex supply chain decisions without human intervention

- Predictive Capability Enhancement: Improved prediction accuracy through advanced machine learning algorithms

- Natural Language Processing: AI systems capable of processing unstructured data sources for risk intelligence

- Computer Vision Applications: Visual monitoring and analysis of supply chain operations and conditions

Blockchain and Distributed Ledger Technology:

- Supply Chain Transparency: Complete visibility and traceability throughout global supply chains

- Smart Contract Automation: Automated execution of supply chain agreements and transactions

- Trust and Verification: Secure, tamper-proof records of supply chain transactions and certifications

- Decentralized Coordination: Distributed coordination mechanisms for complex supply chain networks

Internet of Things Evolution:

- Ubiquitous Monitoring: Comprehensive sensor networks providing real-time visibility into all supply chain assets

- Edge Computing Integration: Local processing capabilities for immediate response to changing conditions

- Predictive Maintenance: Advanced maintenance strategies based on real-time equipment monitoring

- Environmental Monitoring: Comprehensive tracking of environmental conditions throughout supply chains

Regulatory and Policy Evolution

Sustainability Regulations:

- Carbon Reporting Requirements: Mandatory reporting of supply chain carbon emissions and reduction efforts

- Circular Economy Mandates: Regulations requiring circular economy principles in supply chain design

- Social Responsibility Standards: Enhanced requirements for labor practices and community impact

- Environmental Impact Assessment: Comprehensive environmental impact assessment requirements

Trade Policy Development:

- Supply Chain Security: Enhanced focus on supply chain security and resilience in trade policy

- Critical Material Management: Government involvement in securing access to critical materials

- Regional Trade Agreements: Evolution of trade agreements to include resilience and security considerations

- Technology Transfer Restrictions: Increasing restrictions on technology transfer and collaboration

Market and Competitive Evolution

Customer Expectation Changes:

- Transparency Demands: Increasing customer requirements for supply chain transparency and sustainability

- Reliability Expectations: Higher expectations for consistent, reliable supply chain performance

- Customization Requirements: Demand for increasingly customized products and services

- Speed and Flexibility: Expectations for rapid response to changing customer needs

Competitive Landscape Shifts:

- Resilience as Differentiator: Supply chain resilience becoming key competitive advantage

- Ecosystem Competition: Competition between entire supply chain ecosystems rather than individual companies

- Technology Leadership: Technology capability becoming critical competitive factor

- Sustainability Leadership: Environmental and social performance affecting competitive position

10 · Strategic Implementation Considerations

Assessment and Planning Framework

Organizational Readiness Evaluation: Organizations should begin resilience transformation with comprehensive assessment of current capabilities and strategic objectives:

- Current State Analysis: Detailed evaluation of existing supply chain capabilities, risks, and performance

- Future State Vision: Clear definition of desired resilience capabilities and business outcomes

- Gap Identification: Systematic identification of capability gaps and development priorities

- Resource Requirements: Understanding of investment requirements and resource allocation needs

Strategic Priority Setting:

- Business Impact Assessment: Evaluation of potential business impact from various resilience initiatives

- Risk-Return Analysis: Comprehensive analysis of risks and returns for different investment options

- Stakeholder Alignment: Ensuring alignment among leadership, functional teams, and external partners

- Timeline Development: Realistic timeline development considering organizational capacity and market dynamics

Implementation Success Factors

Leadership and Governance:

- Executive Sponsorship: Strong leadership commitment and visible support for resilience initiatives

- Cross-Functional Coordination: Effective coordination across all functions and organizational levels

- Clear Accountability: Well-defined roles, responsibilities, and accountability for resilience outcomes

- Decision-Making Authority: Appropriate authority and empowerment for resilience leaders and teams

Capability Development:

- Skill Building: Comprehensive development of technical and analytical skills required for resilience

- Knowledge Management: Effective systems for capturing, sharing, and applying resilience knowledge

- Continuous Learning: Ongoing learning and adaptation based on experience and changing conditions

- Innovation Culture: Environment that encourages innovation and experimentation in resilience approaches

Technology and Process Integration:

- System Integration: Seamless integration of technology systems and data sources

- Process Standardization: Standardized processes that support resilience across all operations

- Automation Utilization: Appropriate use of automation to enhance resilience capabilities

- Data Quality Management: High-quality data foundation supporting effective decision-making

Long-Term Strategic Positioning

Competitive Advantage Development: Organizations that successfully implement comprehensive resilience strategies often achieve sustainable competitive advantages:

- Market Leadership: Superior reliability and service performance during industry disruptions

- Customer Loyalty: Strong customer relationships built on consistent performance and transparency

- Supplier Partnerships: Preferred customer status with key suppliers through collaborative resilience initiatives

- Operational Excellence: Lower costs and higher efficiency through optimized, resilient operations

- Innovation Leadership: Advanced capabilities attracting top talent and enabling breakthrough innovations

- Brand Value: Enhanced reputation for reliability, sustainability, and responsible business practices

Ecosystem Leadership Opportunities:

- Industry Collaboration: Leadership role in industry-wide resilience initiatives and standard-setting

- Supply Chain Orchestration: Coordination and optimization of entire supply chain ecosystems

- Technology Platform Development: Platform leadership enabling resilience for multiple stakeholders

- Regulatory Influence: Active participation in policy development and regulatory standard-setting

Future-Proofing Strategies:

- Adaptability Emphasis: Building capabilities that can adapt to unknown future challenges

- Scenario Planning: Regular scenario planning for multiple potential future environments

- Continuous Innovation: Ongoing investment in emerging technologies and approaches

- Learning Organization: Systematic capture and application of lessons learned from disruptions and responses

11 · Industry-Specific Resilience Considerations

Manufacturing and Industrial Operations

Unique Challenges:

- Just-in-Time Dependencies: Balancing efficiency with resilience in lean manufacturing environments

- Complex Equipment Dependencies: Managing risks associated with specialized, critical manufacturing equipment

- Quality and Safety Requirements: Maintaining quality and safety standards during disruptions and recovery

- Regulatory Compliance: Meeting industry-specific regulatory requirements while managing disruptions

Specialized Strategies:

- Production Flexibility: Manufacturing systems capable of producing multiple products and adjusting volumes

- Supplier Development Programs: Deep partnerships with suppliers including joint resilience planning

- Predictive Maintenance: Advanced maintenance strategies preventing equipment failures

- Quality Assurance Integration: Quality systems that function effectively during disruptions

Retail and Consumer Goods

Market-Specific Factors:

- Seasonal Demand Patterns: Managing inventory and capacity for highly seasonal products

- Fashion and Trend Sensitivity: Rapid product lifecycle changes affecting supply chain planning

- Consumer Expectation Management: Maintaining customer satisfaction during service disruptions

- Private Label Complexity: Managing resilience across diverse private label supply chains

Tailored Approaches:

- Demand Sensing Technology: Advanced forecasting for volatile consumer demand patterns

- Flexible Sourcing Strategies: Rapid adjustment of sourcing based on market conditions

- Omnichannel Integration: Seamless customer experience across multiple retail channels

- Sustainable Supply Practices: Integration of sustainability requirements with resilience strategies

Healthcare and Pharmaceuticals

Critical Requirements:

- Patient Safety Priority: Ensuring patient safety and product quality during all disruptions

- Regulatory Compliance: Meeting strict pharmaceutical and medical device regulations

- Cold Chain Management: Maintaining temperature-controlled supply chains for sensitive products

- Emergency Response: Rapid response capabilities for public health emergencies

Specialized Solutions:

- Redundant Quality Systems: Multiple quality assurance mechanisms ensuring product safety

- Emergency Stockpiling: Strategic inventory positioning for critical medical supplies

- Regulatory Relationship Management: Close coordination with regulatory agencies during disruptions

- Healthcare Provider Collaboration: Direct partnership with healthcare providers for supply planning

Technology and Electronics

Industry Dynamics:

- Rapid Innovation Cycles: Managing supply chains for products with short lifecycles

- Global Component Dependencies: Complex global supply networks for electronic components

- Geopolitical Sensitivities: Managing supply chains affected by technology transfer restrictions

- Quality and Reliability Requirements: High-quality standards for electronic products and components

Strategic Responses:

- Component Diversification: Multiple sourcing strategies for critical electronic components

- Technology Localization: Regional production capabilities for sensitive technologies

- Innovation Partnership: Collaborative innovation with suppliers and technology partners

- Intellectual Property Protection: Supply chain strategies protecting proprietary technologies

12 · Financial Management and Investment Strategy

Investment Framework for Resilience

Cost-Benefit Analysis: Effective resilience investment requires comprehensive analysis of costs and benefits across multiple time horizons:

Direct Costs:

- Technology Infrastructure: Investment in systems, platforms, and analytical capabilities

- Process Redesign: Costs associated with redesigning supply chain processes and procedures

- Training and Development: Investment in building organizational capabilities and skills

- Supplier Development: Costs for developing supplier capabilities and relationships

Indirect Costs:

- Operational Complexity: Additional complexity in managing more sophisticated supply chain operations

- Opportunity Costs: Alternative uses of capital and resources for resilience investments

- Change Management: Costs associated with organizational change and transformation

- Ongoing Maintenance: Continuing costs for maintaining resilience capabilities

Quantifiable Benefits:

- Cost Avoidance: Reduced costs from avoiding disruptions and emergency responses

- Revenue Protection: Revenue maintained during disruptions that would otherwise be lost

- Efficiency Improvements: Operational efficiency gains from optimized processes and systems

- Risk Mitigation: Reduced insurance costs and financial exposure from improved risk management

Strategic Benefits:

- Competitive Advantage: Market position improvements from superior reliability and service

- Customer Relationships: Enhanced customer loyalty and relationship value

- Supplier Partnerships: Improved supplier relationships and preferential treatment

- Brand Value: Enhanced reputation and brand value from sustainability and reliability

Financial Risk Management

Working Capital Optimization:

- Inventory Strategy: Optimal inventory positioning balancing service levels with carrying costs

- Cash Flow Management: Managing cash flow implications of resilience investments and operations

- Supplier Payment Terms: Negotiating payment terms that support mutual resilience objectives

- Currency Risk Management: Managing foreign exchange risks in global supply chains

Insurance and Risk Transfer:

- Supply Chain Insurance: Comprehensive insurance coverage for supply chain disruptions

- Parametric Insurance: Weather and catastrophe insurance providing rapid payouts

- Cyber Insurance: Protection against cybersecurity risks affecting supply chain operations

- Political Risk Insurance: Coverage for geopolitical risks in international operations

13 · Stakeholder Engagement and Communication

Internal Stakeholder Alignment

Executive Leadership Engagement:

- Strategic Vision Communication: Clear articulation of resilience strategy and business value

- Investment Justification: Comprehensive business case for resilience investments

- Progress Reporting: Regular reporting on resilience initiative progress and outcomes

- Decision Support: Providing leadership with information needed for strategic decisions

Cross-Functional Coordination:

- Shared Objectives: Aligned objectives across all functions supporting resilience goals

- Collaborative Planning: Joint planning processes ensuring coordination across functions

- Performance Integration: Integrated performance measurement across functional areas

- Resource Coordination: Coordinated resource allocation supporting resilience objectives

Employee Engagement:

- Training and Development: Comprehensive training programs building resilience capabilities

- Communication Programs: Regular communication about resilience initiatives and progress

- Recognition and Incentives: Recognition and incentive programs supporting resilience behaviors

- Feedback Mechanisms: Systems for capturing employee feedback and suggestions

External Stakeholder Management

Supplier Relationship Development:

- Strategic Partnership: Deep partnerships with key suppliers supporting mutual resilience

- Capability Development: Investment in supplier capabilities and resilience

- Information Sharing: Open communication and information sharing with suppliers

- Joint Planning: Collaborative planning and risk management with suppliers

Customer Communication:

- Transparency: Open communication about supply chain capabilities and potential risks

- Service Level Agreements: Clear agreements about service levels and performance expectations

- Disruption Communication: Proactive communication during disruptions and recovery

- Value Demonstration: Clear communication of value delivered through resilience capabilities

Regulatory and Government Relations:

- Compliance Management: Proactive compliance with all applicable regulations

- Industry Collaboration: Participation in industry associations and standard-setting bodies

- Policy Engagement: Active engagement in policy development affecting supply chain resilience

- Emergency Coordination: Coordination with government agencies during emergency situations

14 · Conclusion and Strategic Recommendations

Key Strategic Insights

Paradigm Shift Recognition: Supply chain resilience has evolved from defensive risk management to proactive competitive strategy. Organizations that recognize this shift and invest accordingly will gain significant advantages over competitors who view resilience merely as cost protection.

Integration Imperative: Successful resilience requires integration across technology, processes, people, and partnerships. Isolated improvements in individual areas cannot deliver the comprehensive resilience needed for today’s complex operating environment.

Continuous Evolution Requirement: The threat landscape, technology capabilities, and competitive environment continue to evolve rapidly. Static resilience strategies quickly become obsolete, requiring continuous adaptation and improvement.

Implementation Recommendations

Foundation Building:

- Executive Commitment: Secure strong, visible leadership commitment to resilience transformation

- Cross-Functional Team Formation: Establish dedicated, empowered teams with clear accountability

- Current State Assessment: Conduct comprehensive assessment of existing capabilities and gaps

- Technology Infrastructure: Invest in data integration and analytical capabilities as foundation

Capability Development:

- Predictive Analytics: Implement machine learning and AI capabilities for disruption prediction

- Network Flexibility: Develop geographic and supplier diversification strategies

- Collaboration Platforms: Deploy technology platforms enabling seamless stakeholder collaboration

- Performance Management: Establish comprehensive measurement and continuous improvement systems

Ecosystem Integration:

- Supplier Development: Invest in supplier capabilities and collaborative resilience planning

- Customer Engagement: Develop transparent communication and value demonstration with customers

- Industry Collaboration: Participate actively in industry resilience initiatives and standard-setting

- Regulatory Engagement: Maintain proactive engagement with regulatory agencies and policy makers

Future Preparedness

Emerging Technology Adoption:

- Artificial Intelligence: Develop capabilities in AI-driven optimization and decision-making

- Digital Twin Technology: Implement comprehensive digital representations of supply chain networks

- Blockchain Integration: Explore blockchain applications for transparency and trust

- IoT and Edge Computing: Deploy sensor networks and local processing capabilities

Adaptability Enhancement:

- Scenario Planning: Regular scenario planning for multiple potential future environments

- Learning Organization: Build systematic capabilities for learning from disruptions and changes

- Innovation Culture: Foster innovation and experimentation in resilience approaches

- Change Management: Develop organizational capacity for managing continuous change

Strategic Positioning:

- Competitive Differentiation: Leverage resilience capabilities for market differentiation

- Ecosystem Leadership: Pursue leadership roles in supply chain ecosystem development

- Sustainability Integration: Integrate environmental and social considerations with resilience strategy

- Global Perspective: Maintain global awareness of trends affecting supply chain resilience

Final Considerations

The journey toward comprehensive supply chain resilience requires sustained commitment, significant investment, and continuous adaptation. However, organizations that successfully build these capabilities will be positioned not only to survive future disruptions but to thrive and gain competitive advantage during periods of uncertainty.

The convergence of technological advancement, regulatory evolution, and market dynamics creates both unprecedented challenges and remarkable opportunities. Success will belong to organizations that view resilience as strategic capability rather than operational necessity, and that invest in building comprehensive, integrated resilience across all aspects of their supply chain operations.

The path forward requires balancing multiple considerations including cost efficiency, service quality, risk mitigation, and competitive positioning. Organizations that successfully navigate these trade-offs while building adaptive, learning-oriented capabilities will emerge as leaders in the next generation of global supply chain management.

This comprehensive analysis provides strategic frameworks and practical insights for building supply chain resilience in an increasingly complex and volatile global environment. Organizations seeking to develop specific resilience strategies tailored to their unique operational requirements and market conditions may benefit from professional consultation with experienced supply chain strategy practitioners.