Executive Summary

The convergence of labor market pressures, technological advancement, and competitive demands is driving unprecedented adoption of automation technologies in warehouse and distribution operations. Understanding the capabilities, implementation requirements, and strategic implications of these technologies is essential for logistics professionals and supply chain leaders planning operational transformation initiatives.

Warehouse Automation and AI Robotics: Strategic Technology Analysis and Implementation Framework

(从AMR到AI拣选——2025年仓库自动化攻略)

1 · Understanding the Strategic Context of Warehouse Automation

The rapid advancement and adoption of warehouse automation technologies reflects fundamental changes in labor markets, customer expectations, and competitive dynamics across the logistics industry. Organizations are increasingly viewing automation not merely as cost reduction tools, but as essential capabilities for operational excellence and competitive differentiation.

Market Drivers and Economic Context

Labor Market Evolution: The logistics industry faces persistent labor challenges that automation technologies can help address:

Demographic and Skills Challenges:

- Labor Shortage: Chronic shortage of warehouse workers across major logistics markets

- Wage Inflation: Rising labor costs affecting operational economics and profitability

- Skills Gap: Mismatch between available workers and technical skills required for modern operations

- Retention Issues: High turnover rates creating training costs and operational disruption

- Safety Concerns: Worker safety issues driving demand for human-robot collaboration solutions

Operational Performance Pressures:

- Customer Expectations: Increasing demands for faster, more accurate order fulfillment

- Peak Season Management: Seasonal volume spikes requiring flexible capacity solutions

- Quality Standards: Enhanced accuracy and consistency requirements for order fulfillment

- Competitive Differentiation: Automation capabilities becoming competitive differentiators

Economic and Financial Considerations:

- Technology Cost Reduction: Declining costs of robotic and automation technologies

- Return on Investment: Improving ROI calculations for automation investments

- Capital Availability: Enhanced availability of financing for technology investments

- Risk Mitigation: Automation reducing operational risk and improving business continuity

Technology Maturation and Market Evolution

Technological Advancement Trends: Modern warehouse automation represents the convergence of multiple technology streams:

Artificial Intelligence and Machine Learning:

- Computer Vision: Advanced image recognition and object identification capabilities

- Predictive Analytics: Demand forecasting and capacity optimization algorithms

- Route Optimization: Dynamic routing and task assignment optimization

- Quality Control: Automated quality inspection and error detection systems

Robotics and Mechanical Systems:

- Autonomous Navigation: Advanced navigation systems enabling flexible robot deployment

- Human-Robot Collaboration: Safe interaction between humans and robots in shared workspaces

- Adaptive Manipulation: Robotic systems capable of handling diverse products and packaging

- Integrated Systems: Seamless integration between different automation technologies

Digital Integration and Connectivity:

- Internet of Things (IoT): Sensor networks providing real-time operational visibility

- Cloud Computing: Scalable computing resources supporting complex automation algorithms

- Edge Computing: Local processing capabilities enabling real-time decision-making

- System Integration: APIs and integration platforms connecting diverse technology systems

2 · Comprehensive Technology Portfolio Analysis

Understanding the capabilities and applications of different automation technologies enables informed decision-making about technology selection and implementation strategies.

Autonomous Mobile Robots (AMRs) and Navigation Systems

Technology Capabilities and Applications: Autonomous Mobile Robots represent one of the most versatile and rapidly adopted automation technologies:

Core Technical Capabilities:

- Advanced Navigation: LiDAR, computer vision, and simultaneous localization and mapping (SLAM)

- Dynamic Path Planning: Real-time route optimization considering obstacles and traffic

- Load Management: Automated pickup, transport, and delivery of goods and materials

- System Integration: Seamless integration with warehouse management and control systems

Operational Applications:

- Goods-to-Person Picking: Transporting inventory to stationary picking stations

- Put-away Operations: Automated placement of received goods into storage locations

- Cross-Docking: Direct transfer of goods from receiving to shipping areas

- Inventory Management: Cycle counting and inventory verification tasks

- Returns Processing: Handling and routing of returned merchandise

Implementation Considerations:

- Infrastructure Requirements: Minimal infrastructure modification compared to fixed automation

- Scalability: Flexible deployment allowing gradual expansion of robot fleets

- Integration Complexity: Sophisticated integration with existing warehouse management systems

- Change Management: Training and adaptation requirements for human workers

Economic Analysis and ROI: Modern AMR implementations demonstrate compelling economic benefits:

Cost Structure Analysis:

- Capital Investment: Lease options reducing upfront capital requirements

- Labor Displacement: Significant reduction in manual material handling labor

- Productivity Enhancement: Increased throughput and operational efficiency

- Quality Improvement: Reduced errors and improved order accuracy

Performance Metrics:

- Productivity Gains: Typical improvements of 25-50% in relevant operational areas

- Accuracy Improvement: Error rate reductions of 80-95% in automated processes

- Utilization Rates: High utilization rates of 70-85% during operational hours

- Payback Periods: Typical payback periods of 12-24 months for well-implemented systems

Collaborative Robotics and Human-Robot Integration

Collaborative Robot (Cobot) Technology: Collaborative robots enable safe human-robot interaction in shared workspaces:

Safety and Interaction Systems:

- Force Sensing: Immediate response to unexpected contact or resistance

- Vision Systems: Real-time monitoring of human presence and movement

- Speed Limiting: Automatic speed reduction in proximity to human workers

- Emergency Stops: Multiple mechanisms for immediate system shutdown

Application Areas:

- Pick and Pack Operations: Collaborative picking of products and order assembly

- Quality Inspection: Automated inspection with human oversight and exception handling

- Palletizing and Depalletizing: Collaborative loading and unloading of pallets

- Packaging Operations: Automated packaging with human quality control

Implementation Benefits:

- Flexibility: Easy reprogramming for different tasks and product types

- Safety: Enhanced worker safety through elimination of repetitive and hazardous tasks

- Productivity: Consistent performance and extended operating hours

- Quality: Improved accuracy and repeatability in routine tasks

AI Vision Systems and Intelligent Picking Technologies

Computer Vision and Machine Learning: Advanced vision systems enable sophisticated product identification and handling:

Technical Capabilities:

- Object Recognition: Accurate identification of products regardless of orientation or packaging

- Defect Detection: Automated quality inspection and defect identification

- Dimension Measurement: Precise measurement for packaging and shipping optimization

- Barcode and Label Reading: Reliable reading of various identification systems

Picking System Integration:

- Robotic Picking: Integration with robotic arms for automated product selection

- Human Guidance: Visual guidance systems for human pickers

- Quality Verification: Automated verification of pick accuracy and quality

- Exception Handling: Intelligent routing of non-standard items

Learning and Adaptation:

- Continuous Learning: Machine learning algorithms improving performance over time

- New Product Integration: Rapid adaptation to new products and packaging types

- Environmental Adaptation: Performance optimization for different lighting and conditions

- Data Analytics: Comprehensive analytics supporting operational optimization

Heavy-Duty Robotics and Material Handling Systems

Advanced Material Handling Robotics: Specialized robots for handling large, heavy, or complex loads:

Container and Trailer Unloading:

- Automated Unloading: Robotic systems for unloading shipping containers and trailers

- Mixed Load Handling: Capability to handle diverse products and packaging types

- Speed and Efficiency: Significant improvements in unloading speed and consistency

- Safety Enhancement: Elimination of manual handling in confined and hazardous spaces

Palletizing and Depalletizing:

- Mixed Case Palletizing: Intelligent stacking of different product types and sizes

- Load Optimization: Optimization of pallet configuration for stability and space utilization

- Quality Control: Automated inspection of pallet quality and integrity

- Integration with Transportation: Seamless integration with transportation and shipping systems

Performance Characteristics:

- Speed and Throughput: Substantial improvements in material handling speed

- Consistency: Reliable performance regardless of shift, time, or external conditions

- Safety: Elimination of workplace injuries associated with heavy lifting

- Cost Effectiveness: Rapid payback through labor savings and productivity improvements

Digital Orchestration and Intelligent Control Systems

Integrated Control and Optimization Platforms: Sophisticated software systems coordinating multiple automation technologies:

System Integration Capabilities:

- Multi-Technology Coordination: Seamless coordination between different automation systems

- Real-Time Optimization: Dynamic optimization of workflows and resource allocation

- Predictive Analytics: Forecasting and proactive management of operational requirements

- Exception Management: Intelligent handling of exceptions and non-standard situations

Operational Intelligence:

- Performance Monitoring: Real-time monitoring of system performance and efficiency

- Predictive Maintenance: Anticipation of maintenance needs and automated scheduling

- Capacity Planning: Optimization of resource allocation and capacity utilization

- Continuous Improvement: Data-driven identification of optimization opportunities

Integration Architecture:

- API-Based Integration: Standard APIs enabling integration with existing systems

- Cloud and Edge Computing: Hybrid computing architecture supporting real-time operations

- Data Management: Comprehensive data collection, storage, and analysis capabilities

- Security and Reliability: Enterprise-grade security and reliability features

3 · Strategic Implementation Framework and Best Practices

Successful warehouse automation implementation requires systematic planning, phased execution, and comprehensive change management to achieve desired operational and financial outcomes.

Strategic Planning and Assessment

Comprehensive Needs Assessment: Effective automation planning begins with thorough analysis of current operations and future requirements:

Operational Analysis:

- Process Mapping: Detailed mapping of current warehouse processes and workflows

- Performance Baseline: Establishment of current performance metrics and benchmarks

- Bottleneck Identification: Systematic identification of operational constraints and inefficiencies

- Volume Analysis: Analysis of volume patterns, seasonality, and growth projections

Technology Readiness Assessment:

- Infrastructure Evaluation: Assessment of current infrastructure and modification requirements

- System Integration: Analysis of existing systems and integration requirements

- Data Readiness: Evaluation of data quality and availability for automation systems

- Organizational Readiness: Assessment of organizational capabilities and change readiness

Business Case Development:

- Financial Modeling: Comprehensive ROI analysis including all costs and benefits

- Risk Assessment: Identification and quantification of implementation and operational risks

- Scenario Analysis: Analysis of different implementation scenarios and their implications

- Success Metrics: Definition of clear success criteria and measurement approaches

Phased Implementation Strategy

Systematic Deployment Approach: Successful automation implementation typically follows structured, phased approaches:

Phase 1: Foundation and Pilot Preparation and Setup:

- Infrastructure Preparation: Necessary modifications to physical infrastructure and systems

- Technology Selection: Final selection and procurement of automation technologies

- Team Formation: Assembly of implementation team with appropriate skills and authority

- Training Development: Development of training programs for operational staff

Pilot Implementation:

- Limited Scope Deployment: Implementation in limited operational area or product category

- Performance Monitoring: Intensive monitoring of pilot performance and issue identification

- Process Refinement: Adjustment and optimization of processes based on pilot experience

- Success Validation: Validation of expected benefits and readiness for broader deployment

Phase 2: Scaled Deployment Expansion Strategy:

- Systematic Rollout: Gradual expansion of automation across broader operational areas

- Process Integration: Integration of automated processes with existing manual operations

- Performance Optimization: Continuous optimization of system performance and efficiency

- Change Management: Ongoing support for organizational adaptation and skill development

System Integration:

- Technology Coordination: Integration of multiple automation technologies into coherent systems

- Data Integration: Integration of automation data with existing business intelligence systems

- Process Standardization: Standardization of processes across automated and manual operations

- Quality Assurance: Implementation of quality assurance processes for automated operations

Phase 3: Optimization and Advanced Capabilities Advanced System Capabilities:

- Artificial Intelligence Integration: Implementation of AI and machine learning capabilities

- Predictive Analytics: Development of predictive capabilities for maintenance and optimization

- Advanced Orchestration: Implementation of sophisticated workflow orchestration systems

- Continuous Improvement: Establishment of systematic continuous improvement processes

Performance Excellence:

- Operational Excellence: Achievement of world-class performance levels in automated operations

- Innovation Integration: Integration of emerging technologies and innovative approaches

- Competitive Advantage: Development of automation capabilities as competitive differentiators

- Knowledge Leadership: Development of internal expertise and industry leadership capabilities

Change Management and Organizational Development

Human-Centered Automation Strategy: Successful automation implementation requires comprehensive attention to human factors:

Workforce Transition:

- Skills Assessment: Evaluation of current workforce skills and development requirements

- Training Programs: Comprehensive training programs for new technologies and processes

- Career Development: Clear career paths and development opportunities for affected workers

- Communication Strategy: Transparent communication about automation plans and implications

Cultural Transformation:

- Innovation Culture: Development of organizational culture supporting innovation and change

- Collaboration Enhancement: Strengthening of collaboration between human workers and automated systems

- Performance Recognition: Recognition and reward systems supporting automation adoption

- Continuous Learning: Establishment of continuous learning and adaptation capabilities

4 · Industry Applications and Sector-Specific Considerations

Different industry sectors have unique requirements and considerations for warehouse automation implementation, requiring tailored approaches to technology selection and deployment.

E-commerce and Retail Distribution

Sector-Specific Requirements: E-commerce operations face unique challenges that automation can effectively address:

Order Fulfillment Characteristics:

- High SKU Diversity: Large number of different products requiring flexible handling

- Small Order Sizes: Typical orders containing few items requiring efficient picking

- Rapid Order Cycles: Customer expectations for same-day or next-day delivery

- Seasonal Variation: Significant seasonal volume fluctuations requiring scalable solutions

Automation Applications:

- Goods-to-Person Systems: AMRs bringing products to stationary picking stations

- Automated Sorting: High-speed sorting systems for order consolidation

- Packaging Automation: Automated packaging systems optimizing box sizes and materials

- Quality Control: Automated verification of order accuracy before shipping

Performance Outcomes:

- Picking Productivity: Improvements of 200-400% in picking productivity

- Order Accuracy: Error rate reductions to less than 0.1% in automated processes

- Processing Speed: Reduction in order processing time from hours to minutes

- Scalability: Ability to handle seasonal peaks without proportional labor increases

Third-Party Logistics (3PL) Operations

Multi-Client Operational Complexity: 3PL operations must manage diverse client requirements and service levels:

Operational Challenges:

- Client Diversity: Different clients with varying requirements and service levels

- Product Mix Variation: Handling diverse products with different characteristics

- Service Level Agreements: Meeting varied SLA requirements across multiple clients

- Cost Allocation: Accurate allocation of costs across different client operations

Automation Solutions:

- Flexible Automation: Systems capable of adapting to different client requirements

- Modular Deployment: Scalable systems allowing expansion based on client growth

- Performance Tracking: Detailed tracking and reporting of performance by client

- Cost Management: Transparent cost allocation and billing systems

Value Proposition:

- Service Differentiation: Automation capabilities as competitive differentiators

- Cost Competitiveness: Lower operational costs enabling competitive pricing

- Service Quality: Improved accuracy and consistency across all client operations

- Growth Support: Scalable capabilities supporting client growth without proportional cost increases

Manufacturing and Industrial Distribution

Complex Product and Handling Requirements: Manufacturing distribution involves specialized requirements:

Product Characteristics:

- Size and Weight Variation: Products ranging from small components to heavy equipment

- Handling Requirements: Special handling needs for fragile, hazardous, or high-value items

- Quality Standards: Strict quality requirements and traceability needs

- Just-in-Time Delivery: Precise timing requirements for manufacturing support

Specialized Automation:

- Heavy-Duty Robotics: Specialized robots for handling large and heavy items

- Precision Handling: High-precision systems for delicate or valuable products

- Quality Inspection: Automated inspection and testing systems

- Inventory Management: Sophisticated inventory tracking and management systems

Food and Beverage Distribution

Regulatory and Quality Requirements: Food distribution involves unique regulatory and quality considerations:

Compliance Requirements:

- Food Safety: Strict adherence to food safety regulations and standards

- Temperature Control: Maintenance of cold chain integrity throughout operations

- Traceability: Comprehensive tracking for recall and quality management

- Sanitation: Automated systems designed for easy cleaning and sanitization

Specialized Technologies:

- Cold Storage Automation: Robots designed for operation in refrigerated environments

- Sanitary Design: Systems designed to meet food safety and sanitation standards

- Automated Inspection: Quality inspection systems for food safety compliance

- Lot Tracking: Sophisticated systems for product traceability and recall management

5 · Case Studies in Automation Implementation

Understanding real-world implementation experiences provides valuable insights for planning and executing successful automation initiatives.

Case Study 1: Large E-commerce Retailer Automation Program

Company Profile: Major e-commerce retailer with multiple distribution centers serving diverse product categories and customer segments

Automation Challenge: The company faced increasing labor costs, difficulty finding qualified workers, and customer demands for faster delivery while maintaining high accuracy standards.

Comprehensive Automation Strategy:

Phase 1: Pilot Implementation

- Technology Selection: Deployment of 20 AMRs in one distribution center for initial testing

- Process Integration: Integration with existing warehouse management system

- Performance Monitoring: Intensive monitoring of productivity, accuracy, and system reliability

- Worker Training: Comprehensive training program for warehouse staff

Phase 2: Multi-Technology Integration

- Expanded AMR Deployment: Scaling to 150 AMRs across three distribution centers

- Collaborative Robotics: Addition of collaborative robots for specialized picking tasks

- AI Vision Systems: Implementation of computer vision for quality control and exception handling

- Digital Orchestration: Deployment of advanced orchestration platform coordinating all systems

Phase 3: Advanced Optimization

- Machine Learning Integration: Implementation of predictive analytics for demand forecasting

- Process Optimization: Continuous optimization of workflows and resource allocation

- Performance Analytics: Advanced analytics for operational insights and improvement

- Innovation Pipeline: Ongoing evaluation and integration of emerging technologies

Results and Impact:

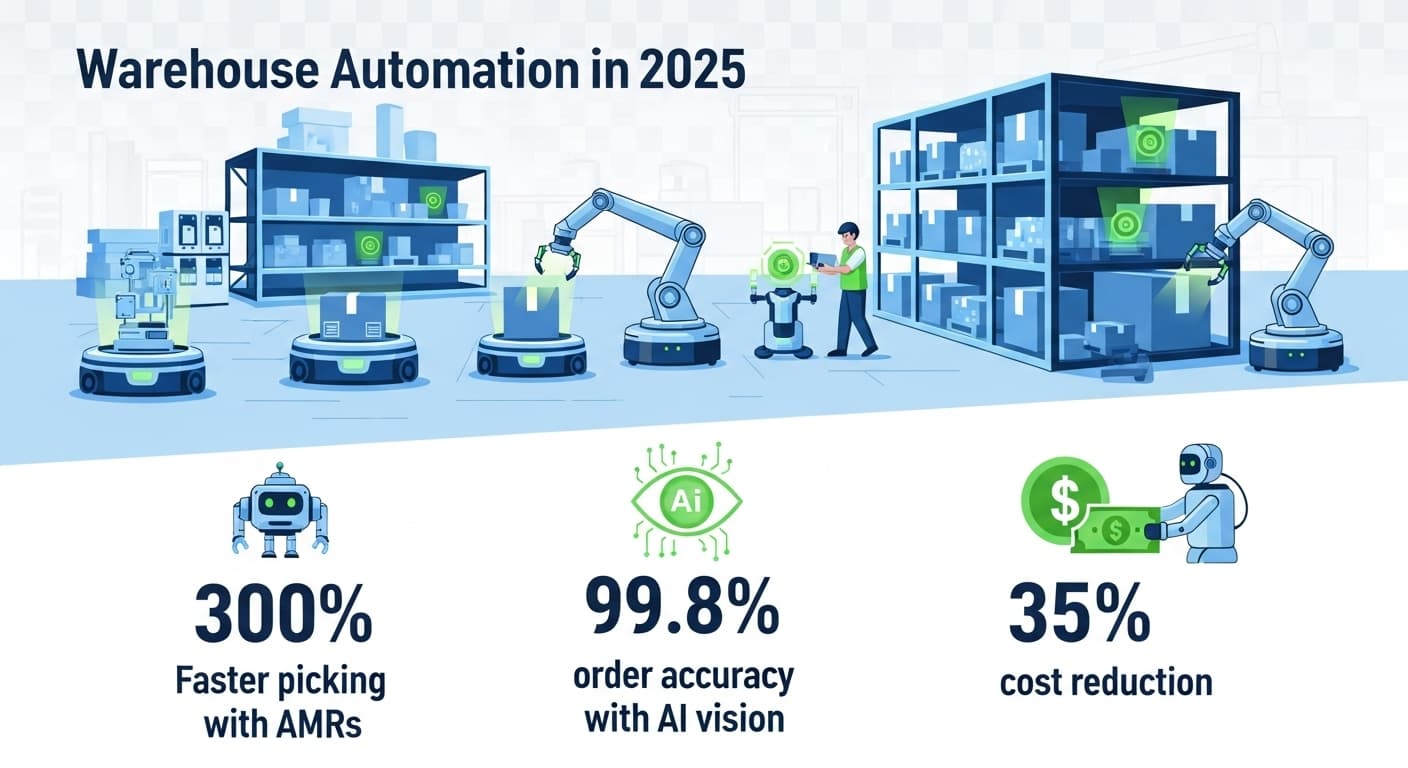

- Productivity Improvement: 300% increase in picking productivity per worker hour

- Accuracy Enhancement: Order accuracy improvement from 98.5% to 99.8%

- Cost Reduction: 35% reduction in operational costs per order

- Service Improvement: 40% reduction in order processing time

- Scalability Achievement: Ability to handle 200% volume increases without proportional labor increases

- Worker Satisfaction: Improved job satisfaction through elimination of repetitive tasks

Case Study 2: Third-Party Logistics Provider Technology Transformation

Company Profile: Regional 3PL serving diverse clients in automotive, consumer goods, and industrial sectors

Implementation Context: The company needed to improve operational efficiency and service quality while managing diverse client requirements and maintaining cost competitiveness.

Tailored Automation Approach:

Client-Specific Solutions:

- Automotive Client: Heavy-duty robotics for large part handling and quality inspection

- Consumer Goods Client: AMRs and collaborative robots for high-volume, diverse product picking

- Industrial Client: Specialized handling systems for technical products and documentation

Integrated Technology Platform:

- Unified Control System: Single platform managing diverse automation technologies

- Client Performance Tracking: Detailed analytics for each client operation

- Flexible Resource Allocation: Dynamic allocation of automation resources based on demand

- Service Level Management: Automated monitoring and management of service level agreements

Implementation Results:

- Service Quality: Improved service levels across all client segments

- Cost Competitiveness: 25% reduction in operational costs enabling competitive pricing

- Client Retention: 100% client retention rate during implementation period

- Business Growth: 60% increase in business volume without proportional cost increases

- Market Position: Enhanced market position through differentiated automation capabilities

Case Study 3: Food Distribution Center Cold Chain Automation

Company Profile: Regional food distributor specializing in frozen and refrigerated products

Unique Implementation Challenges: The company needed to implement automation in challenging cold storage environments while maintaining strict food safety and quality standards.

Specialized Automation Solution:

Cold Environment Technology:

- Cold-Rated Robotics: Specialized robots designed for operation in sub-zero temperatures

- Insulated Control Systems: Control systems designed to operate reliably in cold environments

- Automated Temperature Monitoring: Comprehensive temperature monitoring and control systems

- Cold Chain Compliance: Automated systems ensuring continuous cold chain compliance

Food Safety Integration:

- Sanitary Design: All automation systems designed for easy cleaning and sanitization

- HACCP Compliance: Systems designed to support Hazard Analysis Critical Control Points

- Traceability Systems: Comprehensive tracking for food safety and recall management

- Quality Inspection: Automated quality inspection systems for food safety compliance

Performance Outcomes:

- Operational Efficiency: 45% improvement in operational efficiency despite challenging environment

- Quality Compliance: 100% compliance with food safety regulations throughout implementation

- Cost Management: 30% reduction in labor costs while improving service quality

- Cold Chain Integrity: Enhanced cold chain management and temperature control

- Competitive Advantage: Market differentiation through superior automation capabilities

6 · Financial Analysis and Investment Considerations

Understanding the financial implications of warehouse automation requires comprehensive analysis of costs, benefits, and investment alternatives across different implementation scenarios.

Total Cost of Ownership Analysis

Comprehensive Cost Structure: Automation investments involve multiple cost categories requiring careful analysis:

Capital Investment Components:

- Technology Acquisition: Direct costs of robotic systems, control software, and integration platforms

- Infrastructure Modification: Facility modifications, power systems, and network infrastructure

- Integration Costs: System integration, customization, and testing expenses

- Training and Change Management: Costs associated with workforce training and organizational change

Operational Cost Considerations:

- Maintenance and Support: Ongoing maintenance contracts and technical support services

- Energy Consumption: Power requirements for robotic systems and supporting infrastructure

- Software Licensing: Ongoing software licensing and upgrade costs

- Insurance and Risk Management: Additional insurance coverage for automated systems

Financial Benefit Categories:

- Labor Cost Reduction: Direct savings from reduced labor requirements

- Productivity Improvements: Revenue benefits from increased throughput and capacity

- Quality Enhancement: Cost savings from reduced errors and improved accuracy

- Scalability Benefits: Ability to handle volume increases without proportional cost increases

Return on Investment Modeling

ROI Calculation Framework: Sophisticated ROI analysis considers multiple benefit categories and time horizons:

Quantifiable Benefits:

- Direct Labor Savings: Reduction in direct labor costs from automation

- Indirect Labor Savings: Reduction in supervision and support labor requirements

- Space Utilization: More efficient use of warehouse space through optimized processes

- Inventory Management: Improved inventory accuracy and reduced carrying costs

- Quality Improvements: Reduced costs from errors, returns, and customer service issues

Strategic Benefits:

- Competitive Advantage: Market position improvements from superior operational capabilities

- Service Level Enhancement: Customer satisfaction and retention benefits from improved service

- Business Growth: Revenue growth enabled by enhanced operational capacity and capabilities

- Risk Mitigation: Reduced operational risks and improved business continuity

Sensitivity Analysis:

- Volume Sensitivity: Impact of volume changes on ROI calculations

- Labor Cost Inflation: Effects of changing labor costs on automation benefits

- Technology Evolution: Consideration of technology advancement and obsolescence risks

- Market Changes: Impact of changing market conditions on investment returns

Alternative Financing and Implementation Models

Flexible Investment Approaches: Modern automation implementations offer various financing and deployment models:

Leasing and As-a-Service Models:

- Technology Leasing: Leasing arrangements reducing upfront capital requirements

- Robotics-as-a-Service: Service models where providers retain ownership and provide ongoing support

- Performance-Based Contracts: Agreements based on performance improvements rather than technology acquisition

- Hybrid Models: Combination approaches balancing ownership and service elements

Risk Sharing Arrangements:

- Vendor Partnerships: Collaborative arrangements sharing implementation risks and benefits

- Performance Guarantees: Vendor guarantees of specific performance improvements

- Phased Implementation: Staged approaches allowing validation before full commitment

- Technology Refresh Programs: Built-in technology upgrade and refresh capabilities

7 · Future Trends and Emerging Technologies

Understanding emerging trends and future technology developments enables strategic planning for long-term automation capabilities and competitive positioning.

Artificial Intelligence and Machine Learning Advancement

Next-Generation AI Applications: Emerging AI capabilities will significantly enhance automation sophistication:

Advanced Decision Making:

- Autonomous Operations: Fully autonomous decision-making in complex operational scenarios

- Predictive Optimization: Advanced prediction and optimization of operational performance

- Adaptive Learning: Systems that continuously learn and improve performance without human intervention

- Complex Problem Solving: AI systems capable of handling unprecedented situations and exceptions

Human-AI Collaboration:

- Augmented Intelligence: AI systems enhancing human decision-making and capabilities

- Natural Language Interaction: Voice and natural language interfaces for human-robot interaction

- Contextual Awareness: AI systems understanding complex operational contexts and requirements

- Emotional Intelligence: Systems capable of understanding and responding to human emotional states

Robotics Technology Evolution

Advanced Robotics Capabilities: Next-generation robotics will offer enhanced flexibility and capability:

Enhanced Manipulation:

- Dexterous Handling: Robotic systems with human-like dexterity and manipulation capabilities

- Adaptive Gripping: Gripping systems that automatically adapt to different product characteristics

- Precision Assembly: Robotic systems capable of complex assembly and manufacturing tasks

- Multi-Modal Sensing: Integration of multiple sensing modalities for enhanced environmental awareness

Collaborative Intelligence:

- Swarm Robotics: Coordinated behavior among multiple robotic systems

- Distributed Decision Making: Decentralized intelligence across robotic networks

- Self-Organization: Robotic systems that automatically organize and optimize their own operations

- Emergent Behavior: Complex behaviors emerging from simple robotic interactions

Integration and Ecosystem Development

Comprehensive Technology Ecosystems: Future automation will involve sophisticated integration across multiple technology domains:

IoT and Sensor Networks:

- Ubiquitous Sensing: Comprehensive sensor networks providing complete operational visibility

- Edge Computing: Local processing capabilities enabling real-time response and decision-making

- Digital Twin Integration: Real-time digital representations of physical operations

- Predictive Maintenance: Advanced prediction of maintenance needs and autonomous scheduling

Cloud and Edge Computing:

- Hybrid Computing Architecture: Optimal distribution of computing between cloud and edge resources

- Real-Time Analytics: Instantaneous analysis and response to operational conditions

- Global Optimization: System-wide optimization across multiple facilities and operations

- Continuous Learning: Systems that learn and improve across entire operational networks

8 · Strategic Recommendations and Implementation Guidance

Strategic Planning Framework

Comprehensive Strategy Development: Organizations should approach automation planning with systematic, strategic frameworks:

Business Strategy Alignment:

- Strategic Objectives: Clear alignment between automation investments and business strategy

- Competitive Positioning: Understanding of how automation supports competitive advantage

- Market Requirements: Analysis of customer and market requirements driving automation needs

- Growth Planning: Integration of automation planning with business growth and expansion plans

Technology Strategy Development:

- Technology Roadmap: Long-term technology development and implementation planning

- Integration Architecture: Comprehensive planning for technology integration and interoperability

- Vendor Strategy: Strategic approach to vendor selection and relationship management

- Innovation Pipeline: Systematic evaluation and integration of emerging technologies

Risk Management Framework:

- Implementation Risk: Systematic identification and mitigation of implementation risks

- Technology Risk: Management of technology obsolescence and evolution risks

- Operational Risk: Preparation for operational disruptions and contingency planning

- Financial Risk: Comprehensive financial risk management and mitigation strategies

Implementation Best Practices

Success Factor Framework:

- Executive Leadership: Strong leadership commitment and support for automation initiatives

- Cross-Functional Integration: Effective coordination across all organizational functions

- Change Management: Comprehensive change management supporting organizational transformation

- Continuous Improvement: Systematic approach to ongoing optimization and enhancement

Implementation Excellence:

- Project Management: Professional project management ensuring successful implementation

- Quality Assurance: Rigorous quality assurance processes ensuring system reliability

- Performance Monitoring: Comprehensive monitoring and management of system performance

- Knowledge Management: Systematic capture and sharing of implementation knowledge and experience

Long-Term Strategic Positioning

Competitive Advantage Development: Organizations that successfully implement automation often achieve sustainable competitive advantages:

- Operational Excellence: Superior operational performance creating competitive differentiation

- Service Leadership: Enhanced service capabilities strengthening customer relationships

- Innovation Leadership: Advanced technology capabilities enabling continued innovation

- Market Position: Strong market position through superior operational capabilities

- Talent Attraction: Ability to attract top talent through advanced technology environment

- Financial Performance: Superior financial performance through operational efficiency and growth

Future Readiness:

- Technology Adaptation: Capabilities for adapting to evolving technology landscapes

- Market Responsiveness: Ability to respond quickly to changing market conditions and requirements

- Innovation Capacity: Internal capabilities for continued innovation and advancement

- Scalability: Systems and processes capable of supporting continued growth and expansion

9 · Conclusion and Strategic Recommendations

Key Strategic Insights

Technology Maturation and Market Readiness: Warehouse automation technologies have reached a level of maturity and cost-effectiveness that makes implementation viable for organizations across a wide range of sizes and operational characteristics. The convergence of technological advancement, economic pressures, and competitive requirements creates compelling business cases for automation investment.

Implementation Success Factors: Successful automation implementation requires comprehensive planning, systematic execution, and strong change management. Organizations that approach automation strategically, with clear business objectives and thorough implementation planning, achieve superior results and sustainable competitive advantages.

Long-Term Value Creation: Automation investments create value not only through cost reduction but also through enhanced capabilities, improved service quality, and competitive differentiation. Organizations should view automation as strategic capability development rather than simply operational cost reduction.

Recommendations for Different Organization Types

Large Enterprise Operations:

- Comprehensive Strategy: Develop enterprise-wide automation strategy with coordinated implementation across multiple facilities

- Advanced Technology: Invest in cutting-edge technologies and advanced integration capabilities

- Innovation Leadership: Pursue leadership positions in automation innovation and industry standard-setting

- Talent Development: Build internal expertise and capabilities for ongoing automation advancement

Mid-Size Operations:

- Focused Implementation: Target automation investments in areas with clearest ROI and business impact

- Phased Approach: Implement automation in phases, building capabilities and experience over time

- Partnership Strategy: Leverage vendor partnerships and service providers for specialized expertise

- Scalable Solutions: Choose automation solutions that can scale with business growth and expansion

Emerging and Growing Operations:

- Strategic Foundation: Build automation capabilities as foundation for competitive advantage and growth

- Flexible Solutions: Choose automation technologies that provide operational flexibility and adaptability

- Service Provider Leverage: Utilize automation service providers and as-a-service models to minimize capital requirements

- Learning Orientation: Emphasize learning and capability building for long-term success

Final Considerations

The warehouse automation landscape offers unprecedented opportunities for operational improvement, competitive differentiation, and long-term value creation. Organizations that approach these opportunities strategically, with comprehensive planning and systematic execution, will be best positioned to achieve sustainable success in increasingly competitive markets.

The key to success lies not in the technology itself, but in the strategic thinking, implementation excellence, and organizational development that enable technology to deliver its full potential. Organizations that invest in building these capabilities, alongside their technology investments, will achieve superior results and sustainable competitive advantages.

The future belongs to organizations that can effectively integrate advanced technology with human capabilities, creating operational systems that are both highly efficient and adaptable to changing market conditions and customer requirements.

This comprehensive analysis provides strategic insights and practical guidance for warehouse automation implementation. Organizations considering automation investments or seeking to optimize their automation strategies may benefit from professional consultation with experienced automation specialists and logistics technology experts who can provide guidance tailored to specific operational requirements and strategic objectives.