Executive Summary

Zone skipping represents a sophisticated logistics strategy that can significantly reduce domestic shipping costs by consolidating parcels for line-haul transportation and utilizing regional carrier networks for final delivery. Understanding the operational requirements, cost structures, and implementation considerations is essential for organizations seeking to optimize their domestic distribution strategies and improve cost competitiveness.

Zone Skipping Strategies: Advanced Cost Optimization for Domestic Distribution

(如何通过"Zone Skipping"在2025年削减美国境内配送成本)

1 · Understanding Zone Skipping: Strategic Context and Operational Framework

Zone skipping represents a fundamental shift from traditional parcel shipping models, leveraging consolidated transportation and regional distribution networks to achieve significant cost reductions while maintaining service quality. This strategy has become increasingly important as shipping costs continue to rise and customer expectations for fast, affordable delivery intensify.

Conceptual Foundation and Strategic Rationale

Traditional Parcel Shipping Challenges: The conventional approach to domestic parcel shipping faces several structural inefficiencies:

Distance-Based Pricing Structure:

- Zone-Based Rates: Carrier pricing that increases dramatically with shipping distance

- Individual Package Economics: Each package bears the full cost of long-distance transportation

- Dimensional Weight Impacts: Low-density packages incur disproportionate costs

- Surcharge Accumulation: Multiple surcharges and accessorial fees increasing total costs

Operational Inefficiencies:

- Redundant Transportation: Multiple packages following similar routes independently

- Network Underutilization: Inefficient use of carrier network capacity

- Limited Consolidation: Missed opportunities for economies of scale in transportation

- Cost Predictability: Difficulty in predicting and controlling shipping costs

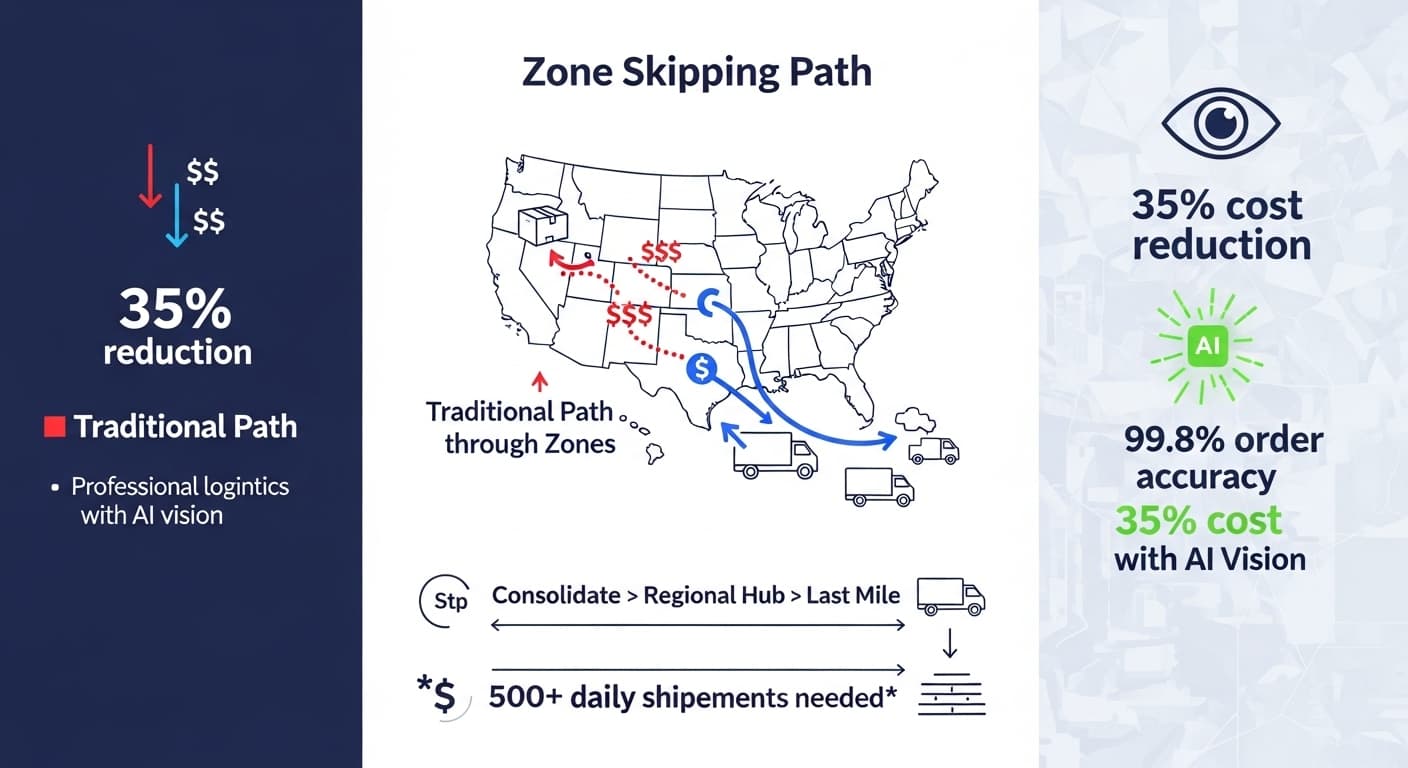

Zone Skipping Strategic Response: Zone skipping addresses these challenges through systematic consolidation and strategic use of regional carrier networks:

Consolidation Benefits:

- Transportation Efficiency: Single freight movement replacing multiple parcel shipments

- Cost Structure Optimization: Freight rates plus regional delivery costs replacing zone-based parcel rates

- Economies of Scale: Better utilization of transportation capacity and resources

- Service Level Maintenance: Comparable or improved delivery times through optimized routing

Network Optimization:

- Regional Injection Points: Strategic placement of packages closer to final destinations

- Carrier Network Leverage: Utilization of regional carriers’ cost-effective last-mile capabilities

- Routing Optimization: More efficient routing through consolidated transportation

- Capacity Utilization: Better utilization of available transportation and handling capacity

Operational Framework and Process Flow

Zone Skipping Process Architecture: Successful zone skipping implementation requires sophisticated operational coordination:

Order Aggregation and Consolidation:

- Geographic Clustering: Grouping orders by destination regions for consolidation

- Volume Optimization: Accumulating sufficient volume for efficient freight transportation

- Timing Coordination: Balancing consolidation benefits with service time requirements

- Package Optimization: Efficient packaging and palletization for freight transportation

Transportation Management:

- Freight Coordination: Managing line-haul transportation to regional injection points

- Route Optimization: Selecting optimal transportation routes and carriers

- Capacity Management: Efficient utilization of freight capacity and resources

- Performance Monitoring: Tracking transportation performance and cost effectiveness

Regional Network Integration:

- Carrier Coordination: Managing relationships with regional delivery carriers

- Injection Point Management: Efficient handoff processes at regional distribution points

- Service Level Management: Maintaining delivery performance standards

- Exception Handling: Managing exceptions and service disruptions

2 · Economic Analysis and Cost Structure Optimization

Understanding the economic fundamentals of zone skipping requires comprehensive analysis of cost structures, volume requirements, and financial performance across different operational scenarios.

Comprehensive Cost Structure Analysis

Traditional Parcel Shipping Cost Components: Understanding the full cost structure of traditional shipping is essential for evaluating zone skipping benefits:

Base Transportation Costs:

- Zone-Based Pricing: Distance-related costs that increase significantly for long-distance shipments

- Weight and Dimensional Pricing: Costs based on actual weight or dimensional weight calculations

- Service Level Premiums: Additional costs for expedited or premium service levels

- Fuel Surcharges: Variable fuel costs affecting all shipments

Accessorial and Surcharge Costs:

- Residential Delivery: Additional costs for residential vs. commercial delivery

- Rural Delivery: Surcharges for delivery to remote or rural areas

- Peak Season Surcharges: Additional costs during high-volume periods

- Address Correction: Fees for incorrect or incomplete addresses

- Special Handling: Costs for oversized, fragile, or special handling requirements

Zone Skipping Cost Structure: Zone skipping replaces the traditional cost structure with a different economic model:

Consolidated Transportation Costs:

- Freight Transportation: Line-haul costs for consolidated shipments to regional points

- Handling and Consolidation: Costs for aggregating and preparing consolidated shipments

- Equipment and Infrastructure: Costs for pallets, containers, and handling equipment

- Fuel and Transportation: Actual fuel and transportation costs for freight movement

Regional Delivery Costs:

- Regional Carrier Rates: Typically lower rates for local and regional delivery

- Last-Mile Optimization: More efficient last-mile delivery through regional networks

- Service Level Consistency: Standardized service levels across regional carriers

- Reduced Surcharges: Lower or eliminated surcharges for regional delivery

Volume Economics and Break-Even Analysis

Volume Threshold Requirements: Zone skipping economics depend heavily on achieving sufficient volume for consolidation:

Minimum Viable Volume:

- Daily Volume Thresholds: Typical requirements of 500-1,000+ packages per day per lane

- Freight Optimization: Volume needed to efficiently utilize freight capacity

- Cost Amortization: Spreading fixed costs across sufficient volume

- Service Frequency: Volume required to maintain acceptable service frequencies

Scaling Benefits:

- Cost Per Package Reduction: Decreasing costs as volume increases

- Freight Efficiency: Better freight utilization with higher volumes

- Negotiating Power: Enhanced negotiating position with carriers and service providers

- Service Improvement: More frequent service and better performance with higher volumes

Break-Even Analysis Framework: Comprehensive break-even analysis considers multiple variables:

Cost Variables:

- Volume Levels: Different volume scenarios and their cost implications

- Distance Factors: Transportation distance affecting freight costs

- Service Requirements: Service level impacts on cost structure

- Seasonal Variations: Impact of seasonal volume fluctuations on economics

Revenue and Margin Impacts:

- Customer Savings: Potential for customer cost savings and competitive advantage

- Margin Improvement: Improved profit margins through reduced shipping costs

- Volume Growth: Potential for volume growth through improved cost competitiveness

- Service Differentiation: Enhanced service capabilities creating additional value

Regional Market Analysis and Lane Optimization

Geographic Market Assessment: Effective zone skipping requires careful analysis of geographic markets and shipping patterns:

Market Density Analysis:

- Order Concentration: Geographic concentration of customer orders

- Delivery Point Density: Number of delivery points in target regions

- Transportation Infrastructure: Availability of transportation and logistics infrastructure

- Competitive Landscape: Regional carrier capabilities and competitive positioning

Lane Development Strategy:

- Primary Lanes: High-volume routes with clear economic benefits

- Secondary Lanes: Medium-volume routes requiring careful economic analysis

- Seasonal Lanes: Routes that may be viable only during peak seasons

- Test Lanes: Experimental routes for evaluating new market opportunities

Performance Optimization:

- Route Efficiency: Optimization of transportation routes and schedules

- Carrier Selection: Strategic selection of freight and regional delivery carriers

- Service Level Management: Balancing cost optimization with service requirements

- Continuous Improvement: Ongoing optimization based on performance data and market changes

3 · Implementation Strategy and Operational Excellence

Successful zone skipping implementation requires systematic planning, careful execution, and ongoing optimization to achieve desired cost savings and service performance.

Strategic Planning and Readiness Assessment

Comprehensive Situation Analysis: Organizations should begin with thorough analysis of current operations and zone skipping potential:

Current State Assessment:

- Shipping Pattern Analysis: Detailed analysis of current shipping volumes, destinations, and costs

- Cost Structure Evaluation: Understanding of current cost structure and optimization opportunities

- Service Performance Baseline: Current service levels and customer satisfaction metrics

- Operational Capabilities: Assessment of internal capabilities and resource requirements

Market Opportunity Analysis:

- Volume Concentration: Identification of geographic areas with sufficient volume concentration

- Cost Savings Potential: Quantification of potential cost savings through zone skipping

- Service Impact Assessment: Analysis of potential service level impacts

- Competitive Implications: Understanding of competitive advantages from zone skipping implementation

Readiness Assessment:

- Technology Infrastructure: Evaluation of systems and technology requirements

- Operational Capabilities: Assessment of internal capabilities for managing zone skipping operations

- Financial Resources: Understanding of investment requirements and financial implications

- Organizational Readiness: Assessment of organizational capacity for managing implementation

Phased Implementation Approach

Systematic Deployment Strategy: Successful zone skipping implementation typically follows a structured, phased approach:

Phase 1: Foundation and Planning Strategic Foundation Development:

- Business Case Development: Comprehensive business case with detailed financial analysis

- Technology Architecture: Design of technology systems and integration requirements

- Operational Process Design: Development of operational processes and procedures

- Partner Selection: Evaluation and selection of freight carriers and regional delivery partners

Infrastructure Preparation:

- System Integration: Integration of zone skipping capabilities with existing systems

- Process Development: Development of consolidation, packaging, and shipping processes

- Training Programs: Development of training programs for operational staff

- Performance Metrics: Establishment of key performance indicators and measurement systems

Phase 2: Pilot Implementation Limited Scope Testing:

- Single Lane Focus: Implementation on one high-volume, high-opportunity lane

- Performance Monitoring: Intensive monitoring of cost, service, and operational performance

- Process Refinement: Adjustment and optimization of processes based on pilot experience

- Issue Resolution: Identification and resolution of operational and technical issues

Validation and Learning:

- Cost Validation: Confirmation of expected cost savings and financial benefits

- Service Impact Assessment: Evaluation of service level impacts and customer satisfaction

- Operational Efficiency: Assessment of operational efficiency and resource requirements

- Scalability Planning: Planning for expansion to additional lanes and higher volumes

Phase 3: Scaled Deployment Multi-Lane Expansion:

- Lane Prioritization: Strategic prioritization of additional lanes based on opportunity and readiness

- System Scaling: Scaling of technology systems and operational processes

- Resource Expansion: Addition of resources and capabilities to support expanded operations

- Performance Optimization: Ongoing optimization of processes and performance

Advanced Capabilities:

- Automation Integration: Implementation of automation technologies for improved efficiency

- Advanced Analytics: Deployment of advanced analytics for optimization and decision-making

- Predictive Capabilities: Development of predictive capabilities for demand forecasting and capacity planning

- Continuous Improvement: Establishment of systematic continuous improvement processes

Technology Integration and System Requirements

Comprehensive Technology Architecture: Zone skipping requires sophisticated technology integration across multiple systems:

Core System Components:

- Order Management Systems: Integration with existing order management and fulfillment systems

- Transportation Management: Advanced transportation management capabilities for freight and parcel coordination

- Warehouse Management: Integration with warehouse management systems for consolidation and packaging

- Carrier Integration: Seamless integration with multiple freight and regional delivery carriers

Data and Analytics Platforms:

- Performance Analytics: Comprehensive analytics for monitoring and optimizing zone skipping performance

- Cost Analysis: Detailed cost analysis and optimization capabilities

- Demand Forecasting: Predictive analytics for volume forecasting and capacity planning

- Route Optimization: Advanced algorithms for optimizing transportation routes and schedules

Integration Architecture:

- API Integration: Standard APIs for seamless integration with carrier and partner systems

- Real-Time Data Exchange: Real-time data exchange for tracking and performance monitoring

- Exception Management: Automated exception handling and alert systems

- Reporting and Dashboards: Comprehensive reporting and dashboard capabilities for performance management

4 · Industry Applications and Sector-Specific Considerations

Zone skipping strategies can be adapted to different industry sectors and business models, each with unique requirements and optimization opportunities.

E-commerce and Direct-to-Consumer Operations

Sector-Specific Characteristics: E-commerce operations present ideal conditions for zone skipping implementation:

Order Pattern Advantages:

- High Volume Concentration: Large numbers of orders to similar geographic regions

- Predictable Patterns: Relatively predictable ordering patterns enabling consolidation planning

- Customer Flexibility: Customers often willing to accept slightly longer delivery times for lower costs

- Seasonal Opportunities: Peak seasons providing additional volume for zone skipping optimization

Implementation Benefits:

- Cost Competitiveness: Significant cost reductions enabling competitive pricing

- Margin Improvement: Direct margin improvement through reduced shipping costs

- Service Differentiation: Ability to offer competitive shipping options

- Growth Enablement: Lower shipping costs enabling expansion into new markets

Strategic Considerations:

- Customer Communication: Clear communication about delivery times and service levels

- Pricing Strategy: Integration of shipping savings into overall pricing strategy

- Service Level Management: Balancing cost savings with customer service expectations

- Peak Season Planning: Special considerations for high-volume periods

Third-Party Logistics (3PL) Operations

Multi-Client Value Proposition: 3PL providers can leverage zone skipping to create value for multiple clients:

Consolidated Benefits:

- Cross-Client Consolidation: Combining volume from multiple clients for greater efficiency

- Service Differentiation: Zone skipping capabilities as competitive differentiators

- Cost Sharing: Shared costs across multiple clients reducing individual client burden

- Expertise Development: Specialized expertise benefiting all clients

Implementation Considerations:

- Client Coordination: Managing coordination across multiple clients and requirements

- Cost Allocation: Fair and transparent allocation of costs and benefits

- Service Level Management: Meeting diverse service level requirements

- Performance Reporting: Detailed reporting of performance and benefits by client

Value Creation:

- Client Savings: Direct cost savings for clients through zone skipping

- Service Enhancement: Enhanced service capabilities and geographic reach

- Revenue Growth: Additional revenue opportunities through value-added services

- Competitive Positioning: Stronger competitive position through advanced capabilities

Manufacturing and Industrial Distribution

B2B Distribution Requirements: Manufacturing and industrial distribution present unique zone skipping opportunities:

Order Characteristics:

- Predictable Patterns: Regular replenishment orders creating predictable volume

- Route Optimization: Opportunities for optimizing delivery routes and schedules

- Customer Relationships: Strong customer relationships enabling collaborative planning

- Service Requirements: Specific service requirements that can be accommodated through zone skipping

Implementation Benefits:

- Cost Management: Significant cost reductions for industrial customers

- Service Reliability: Improved service reliability through consolidated transportation

- Relationship Strengthening: Enhanced customer relationships through cost savings

- Market Expansion: Ability to serve new markets cost-effectively

5 · Case Studies and Implementation Examples

Understanding real-world implementation experiences provides valuable insights for planning and executing successful zone skipping initiatives.

Case Study 1: National Apparel Retailer Distribution Optimization

Company Profile: National apparel retailer with significant direct-to-consumer business and multiple distribution centers

Implementation Challenge: The company faced increasing shipping costs for cross-country shipments while customer expectations for fast, affordable delivery continued to rise.

Zone Skipping Strategy Development:

Market Analysis and Lane Selection:

- Order Pattern Analysis: Comprehensive analysis of order patterns and geographic concentration

- Cost Modeling: Detailed cost modeling comparing traditional shipping with zone skipping

- Service Impact Assessment: Analysis of potential service level impacts

- Partner Selection: Evaluation and selection of freight carriers and regional delivery partners

Phased Implementation Approach:

- West Coast to East Coast Lane: Initial implementation on highest-volume cross-country lane

- System Integration: Integration of zone skipping capabilities with existing fulfillment systems

- Performance Monitoring: Intensive monitoring of cost, service, and customer satisfaction impacts

- Process Optimization: Continuous optimization of consolidation and shipping processes

Technology and Process Integration:

- Advanced Analytics: Implementation of analytics for optimizing consolidation and routing

- Automated Decision-Making: Automated systems for determining when to use zone skipping

- Customer Communication: Enhanced customer communication about delivery options and timing

- Performance Management: Comprehensive performance management and reporting systems

Results and Impact:

- Cost Reduction: 35% reduction in shipping costs for applicable orders

- Service Maintenance: Maintained average delivery times while reducing costs

- Customer Satisfaction: Improved customer satisfaction through lower shipping costs

- Volume Growth: Increased order volume through improved cost competitiveness

- Market Expansion: Ability to serve new geographic markets cost-effectively

Case Study 2: Specialty Food and Beverage Distributor Regional Strategy

Company Profile: Specialty food and beverage distributor serving restaurants and retail customers across multiple regions

Implementation Context: The company needed to improve cost competitiveness while maintaining high service levels for time-sensitive food products.

Customized Zone Skipping Approach:

Product-Specific Considerations:

- Temperature Control: Special handling requirements for temperature-sensitive products

- Shelf Life Management: Inventory rotation and shelf life considerations

- Regulatory Compliance: Food safety and regulatory compliance requirements

- Quality Assurance: Quality control processes throughout consolidated transportation

Regional Network Development:

- Regional Hub Strategy: Development of regional consolidation and distribution hubs

- Local Carrier Partnerships: Partnerships with regional carriers specializing in food distribution

- Cold Chain Management: Maintenance of cold chain integrity throughout zone skipping process

- Service Level Optimization: Balancing cost optimization with customer service requirements

Operational Excellence:

- Inventory Management: Advanced inventory management for consolidated operations

- Quality Control: Comprehensive quality control processes for food safety

- Customer Service: Enhanced customer service and communication capabilities

- Regulatory Compliance: Systematic compliance with food safety and transportation regulations

Performance Outcomes:

- Cost Efficiency: 28% reduction in distribution costs while maintaining service levels

- Service Quality: Improved service reliability and consistency

- Market Reach: Expanded ability to serve distant markets cost-effectively

- Customer Relationships: Strengthened customer relationships through improved service and costs

- Regulatory Compliance: Enhanced compliance with food safety and transportation regulations

Case Study 3: Technology Products E-commerce Platform

Company Profile: E-commerce platform specializing in technology products with global supplier base and diverse customer segments

Strategic Challenge: The company needed to optimize domestic distribution costs while managing diverse product characteristics and customer requirements.

Comprehensive Zone Skipping Implementation:

Multi-Product Strategy:

- Product Segmentation: Different zone skipping strategies for different product categories

- Consolidation Optimization: Advanced algorithms for optimizing mixed-product consolidation

- Handling Requirements: Special considerations for fragile and high-value technology products

- Service Level Differentiation: Different service levels for different customer segments

Advanced Technology Integration:

- Machine Learning: Machine learning algorithms for optimizing consolidation decisions

- Predictive Analytics: Predictive analytics for demand forecasting and capacity planning

- Real-Time Optimization: Real-time optimization of transportation and routing decisions

- Customer Interface: Advanced customer interface for delivery options and tracking

Partnership Strategy:

- Multi-Carrier Network: Partnerships with multiple carriers for redundancy and optimization

- Technology Integration: Deep technical integration with carrier systems and APIs

- Performance Management: Sophisticated performance management and optimization systems

- Continuous Improvement: Systematic continuous improvement processes

Strategic Results:

- Cost Optimization: 42% reduction in shipping costs for applicable orders

- Service Enhancement: Improved delivery options and customer choice

- Technology Leadership: Industry-leading technology integration and customer experience

- Competitive Advantage: Significant competitive advantage through cost and service leadership

- Business Growth: Substantial business growth enabled by improved cost structure

6 · Performance Management and Optimization

Effective zone skipping operations require comprehensive performance management systems and continuous optimization processes to maintain cost effectiveness and service quality.

Key Performance Indicators and Metrics

Comprehensive Performance Framework: Zone skipping performance should be measured across multiple dimensions:

Cost Performance Metrics:

- Cost Per Package: Total cost per package including all freight and regional delivery costs

- Cost Savings: Actual cost savings compared to traditional parcel shipping

- Cost Predictability: Variance in costs and ability to forecast shipping expenses

- Total Cost of Ownership: Comprehensive cost including operational and overhead expenses

Service Performance Indicators:

- Transit Time Performance: Actual delivery times compared to service commitments

- On-Time Delivery: Percentage of shipments delivered within committed time frames

- Service Reliability: Consistency of service performance across different lanes and conditions

- Customer Satisfaction: Customer satisfaction with delivery service and communication

Operational Efficiency Measures:

- Consolidation Efficiency: Percentage of available freight capacity utilized

- Handling Productivity: Efficiency of consolidation and deconsolidation processes

- Exception Rates: Frequency of exceptions and service disruptions

- Resource Utilization: Efficiency of labor and equipment utilization

Strategic Impact Assessment:

- Market Competitiveness: Impact on competitive position and market share

- Customer Acquisition: Contribution to new customer acquisition and retention

- Revenue Growth: Impact on overall revenue growth and business performance

- Return on Investment: Financial return on zone skipping investments and initiatives

Continuous Improvement and Optimization

Systematic Optimization Process: Effective zone skipping operations require ongoing optimization:

Performance Analysis:

- Regular Performance Reviews: Systematic review of performance against targets and benchmarks

- Root Cause Analysis: Identification of performance issues and underlying causes

- Trend Analysis: Analysis of performance trends and patterns over time

- Benchmarking: Comparison with industry benchmarks and best practices

Process Improvement:

- Process Optimization: Continuous improvement of consolidation, transportation, and delivery processes

- Technology Enhancement: Implementation of new technologies and system improvements

- Workflow Design: Optimization of workflows and operational procedures

- Training and Development: Ongoing training and development for operational staff

Strategic Optimization:

- Lane Analysis: Regular analysis of lane performance and optimization opportunities

- Network Design: Optimization of transportation networks and routing

- Carrier Management: Ongoing optimization of carrier relationships and performance

- Service Design: Optimization of service offerings and customer options

Technology and Data Analytics

Advanced Analytics Capabilities: Modern zone skipping operations leverage sophisticated analytics:

Predictive Analytics:

- Demand Forecasting: Predictive models for forecasting shipping volume and patterns

- Capacity Planning: Optimization of freight capacity and resource planning

- Route Optimization: Advanced algorithms for optimizing transportation routes

- Exception Prediction: Predictive models for identifying potential service disruptions

Real-Time Optimization:

- Dynamic Routing: Real-time optimization of transportation routes and schedules

- Capacity Management: Real-time management of freight and handling capacity

- Load Optimization: Dynamic optimization of consolidation and loading processes

- Service Adjustment: Real-time adjustment of service levels and delivery options

Business Intelligence:

- Performance Dashboards: Real-time dashboards for monitoring operational performance

- Cost Analysis: Detailed analysis of costs and profitability by lane and customer

- Market Intelligence: Analysis of market trends and competitive positioning

- Strategic Planning: Analytics supporting strategic planning and decision-making

7 · Strategic Considerations and Future Developments

Understanding emerging trends and strategic considerations enables organizations to position themselves for long-term success in zone skipping and distribution optimization.

Market Evolution and Competitive Dynamics

Industry Transformation Trends: The logistics industry continues to evolve in ways that affect zone skipping strategies:

Technology Advancement:

- Automation Integration: Increased automation in consolidation and handling processes

- Artificial Intelligence: AI-driven optimization of routing and capacity utilization

- IoT and Tracking: Enhanced tracking and visibility throughout the zone skipping process

- Digital Platforms: Advanced platforms for managing multi-party logistics operations

Market Structure Changes:

- Carrier Consolidation: Ongoing consolidation among major carriers affecting pricing and service

- Regional Carrier Growth: Growth and sophistication of regional delivery networks

- Service Provider Evolution: Evolution of 3PL and service provider capabilities

- Customer Expectations: Continued evolution of customer expectations for speed and cost

Regulatory and Policy Considerations:

- Transportation Regulation: Potential changes in transportation regulations affecting operations

- Environmental Standards: Increasing emphasis on environmental sustainability in transportation

- Labor Regulations: Changes in labor regulations affecting transportation and logistics operations

- Trade Policy: International trade policies affecting domestic distribution patterns

Innovation Opportunities and Emerging Technologies

Next-Generation Capabilities: Emerging technologies create new opportunities for zone skipping optimization:

Advanced Automation:

- Robotic Consolidation: Automated systems for packaging and consolidation

- Autonomous Transportation: Potential for autonomous vehicles in line-haul transportation

- Smart Sorting: AI-powered sorting and routing systems

- Predictive Maintenance: Predictive maintenance for transportation equipment and systems

Digital Integration:

- Blockchain Applications: Blockchain technology for tracking and verification

- Digital Twins: Digital twin technology for network optimization and simulation

- API Ecosystems: Comprehensive API ecosystems enabling seamless integration

- Real-Time Visibility: End-to-end real-time visibility throughout the shipping process

Sustainability Integration:

- Carbon Optimization: Optimization for carbon footprint reduction alongside cost optimization

- Green Transportation: Integration of electric and alternative fuel vehicles

- Circular Economy: Integration with circular economy principles and reverse logistics

- Sustainability Reporting: Comprehensive sustainability tracking and reporting

Strategic Planning and Long-Term Positioning

Future-Ready Strategy Development: Organizations should consider long-term trends in developing zone skipping strategies:

Market Positioning:

- Competitive Differentiation: Leveraging zone skipping for competitive advantage

- Service Innovation: Innovation in service offerings and customer experience

- Market Expansion: Using cost advantages to expand into new markets

- Partnership Strategy: Strategic partnerships for enhanced capabilities and reach

Capability Development:

- Technology Investment: Strategic investment in technology and innovation

- Talent Development: Building internal expertise and capabilities

- Network Development: Continuous development and optimization of logistics networks

- Partnership Cultivation: Development of strategic partnerships with carriers and service providers

8 · Implementation Guidance and Strategic Recommendations

Comprehensive Assessment Framework

Strategic Evaluation Process: Organizations considering zone skipping should conduct systematic evaluation:

Business Case Analysis:

- Volume Assessment: Analysis of shipping volumes and geographic concentration

- Cost-Benefit Analysis: Comprehensive analysis of costs, benefits, and return on investment

- Service Impact Evaluation: Assessment of potential service level impacts and customer satisfaction

- Risk Assessment: Identification and evaluation of implementation and operational risks

Readiness Evaluation:

- Operational Capabilities: Assessment of internal capabilities and resource requirements

- Technology Infrastructure: Evaluation of technology systems and integration requirements

- Financial Resources: Understanding of investment requirements and financial implications

- Market Conditions: Analysis of market conditions and competitive implications

Implementation Planning:

- Phased Approach: Development of systematic, phased implementation strategy

- Resource Allocation: Planning for resource allocation and capability development

- Performance Management: Design of performance management and optimization systems

- Risk Mitigation: Development of risk mitigation and contingency planning

Success Factors and Best Practices

Critical Success Elements:

- Executive Leadership: Strong leadership commitment and support for zone skipping initiatives

- Systematic Planning: Comprehensive planning and preparation for implementation

- Technology Investment: Adequate investment in technology systems and capabilities

- Performance Management: Rigorous performance management and continuous improvement

- Partnership Development: Strong partnerships with carriers and service providers

- Customer Focus: Maintaining focus on customer service and satisfaction throughout implementation

Common Pitfalls and Mitigation:

- Volume Forecasting: Accurate volume forecasting and capacity planning

- Service Level Management: Careful management of service level impacts and customer expectations

- Technology Integration: Comprehensive testing and validation of technology integration

- Cost Management: Careful management of all costs including hidden and indirect costs

- Change Management: Effective change management for organizational and process changes

Strategic Recommendations by Organization Type

Large Enterprise Operations:

- Comprehensive Strategy: Development of enterprise-wide zone skipping strategy

- Advanced Technology: Investment in sophisticated technology and analytics capabilities

- Network Optimization: Systematic optimization of entire distribution network

- Innovation Leadership: Leadership in zone skipping innovation and best practices

Mid-Size Operations:

- Focused Implementation: Strategic focus on highest-impact opportunities

- Partnership Leverage: Leveraging partnerships with 3PLs and service providers

- Technology Adoption: Adoption of proven technologies and systems

- Performance Focus: Emphasis on achieving measurable performance improvements

Growing Operations:

- Strategic Foundation: Building zone skipping capabilities as growth enabler

- Scalable Solutions: Implementation of scalable systems and processes

- Learning Orientation: Emphasis on learning and capability development

- Flexible Approach: Maintaining flexibility for changing business requirements

9 · Conclusion and Strategic Outlook

Key Strategic Insights

Market Opportunity Recognition: Zone skipping represents a significant opportunity for cost optimization and competitive advantage in domestic distribution. Organizations that understand and effectively implement zone skipping strategies can achieve substantial cost savings while maintaining or improving service levels.

Implementation Success Factors: Success in zone skipping requires comprehensive planning, systematic execution, and ongoing optimization. Organizations that approach zone skipping strategically, with clear objectives and thorough preparation, achieve superior results.

Long-Term Value Creation: Zone skipping creates value not only through immediate cost savings but also through enhanced competitive positioning, improved customer satisfaction, and operational excellence. Organizations should view zone skipping as a strategic capability rather than simply a cost reduction tactic.

Future Outlook and Strategic Positioning

Continued Market Evolution: The logistics industry will continue to evolve in ways that enhance the value proposition of zone skipping. Technological advancement, changing customer expectations, and competitive pressures will create additional opportunities for zone skipping optimization.

Technology Integration: The integration of advanced technologies including artificial intelligence, automation, and digital platforms will continue to enhance zone skipping capabilities and create new optimization opportunities.

Competitive Advantage: Organizations that successfully implement and optimize zone skipping strategies will gain sustainable competitive advantages through superior cost structures, enhanced service capabilities, and operational excellence.

Final Recommendations

Zone skipping represents a powerful strategy for organizations seeking to optimize domestic distribution costs while maintaining competitive service levels. Success requires strategic thinking, systematic implementation, and ongoing optimization. Organizations that invest in building comprehensive zone skipping capabilities will be positioned for long-term success in increasingly competitive markets.

The key to success lies in understanding that zone skipping is not merely a shipping cost reduction technique, but a comprehensive distribution strategy that can create competitive advantage and enable business growth. Organizations that approach zone skipping with this strategic perspective will achieve the greatest benefits and sustainable success.

This comprehensive analysis provides strategic insights and practical guidance for zone skipping implementation. Organizations considering zone skipping strategies or seeking to optimize their domestic distribution operations may benefit from professional consultation with experienced logistics strategy specialists who can provide guidance tailored to specific operational requirements and market conditions.